OEM & Custom

Sheet Metal Fabrication

Supplier in China

Our company provides one-stop service from mold design, mold making to product mass production, which can be used for prototypes, small batches to mass production, providing you with customized and low-cost sheet metal processing solutions.

Why Choose US for Sheet Metal Fabrication

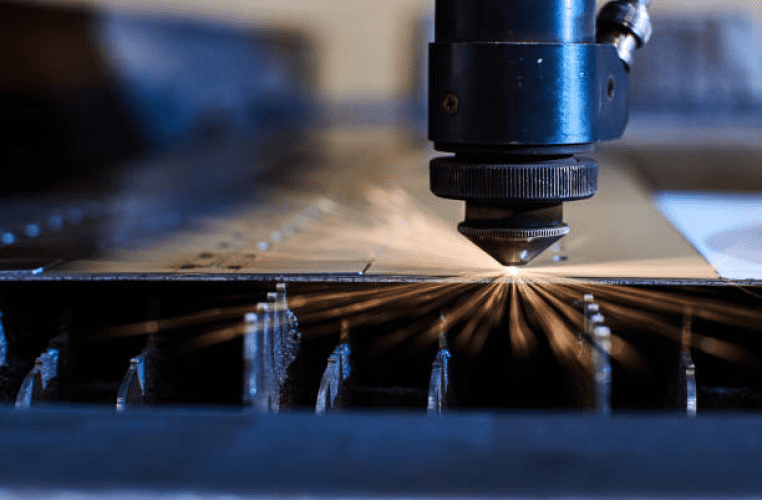

What is Sheet Metal Fabrication?

Sheet metal processing, also known as sheet metal fabrication, involves plastically deforming sheet metal—either by hand or through stamping—into the desired shape and size. These parts can then be further welded or machined to create more complex components.

Key processes include:

- A notable feature of sheet metal fabrication is the consistent thickness of the parts produced. Sheet metal components are characterized by their lightweight, high strength, low cost, and suitability for mass production. This processing method is widely utilized in various industries, including electronics, communications, automotive, and medical equipment.

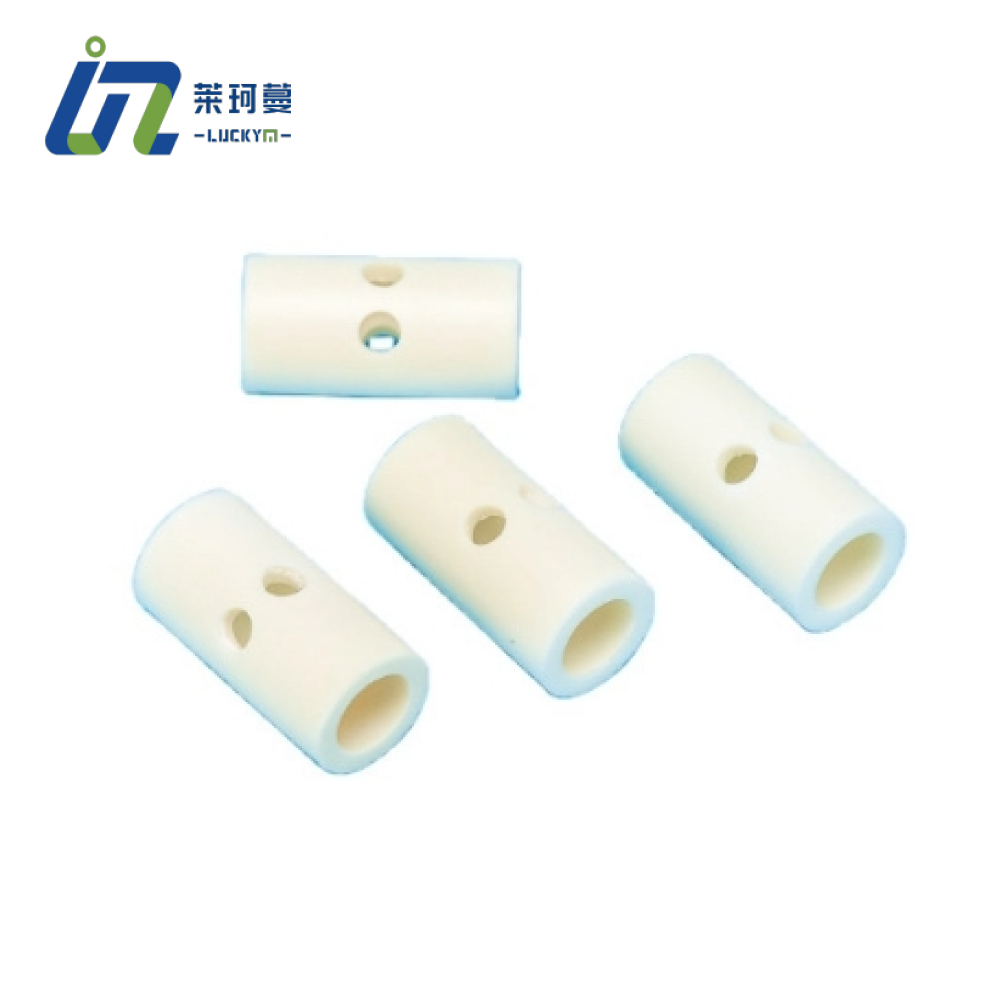

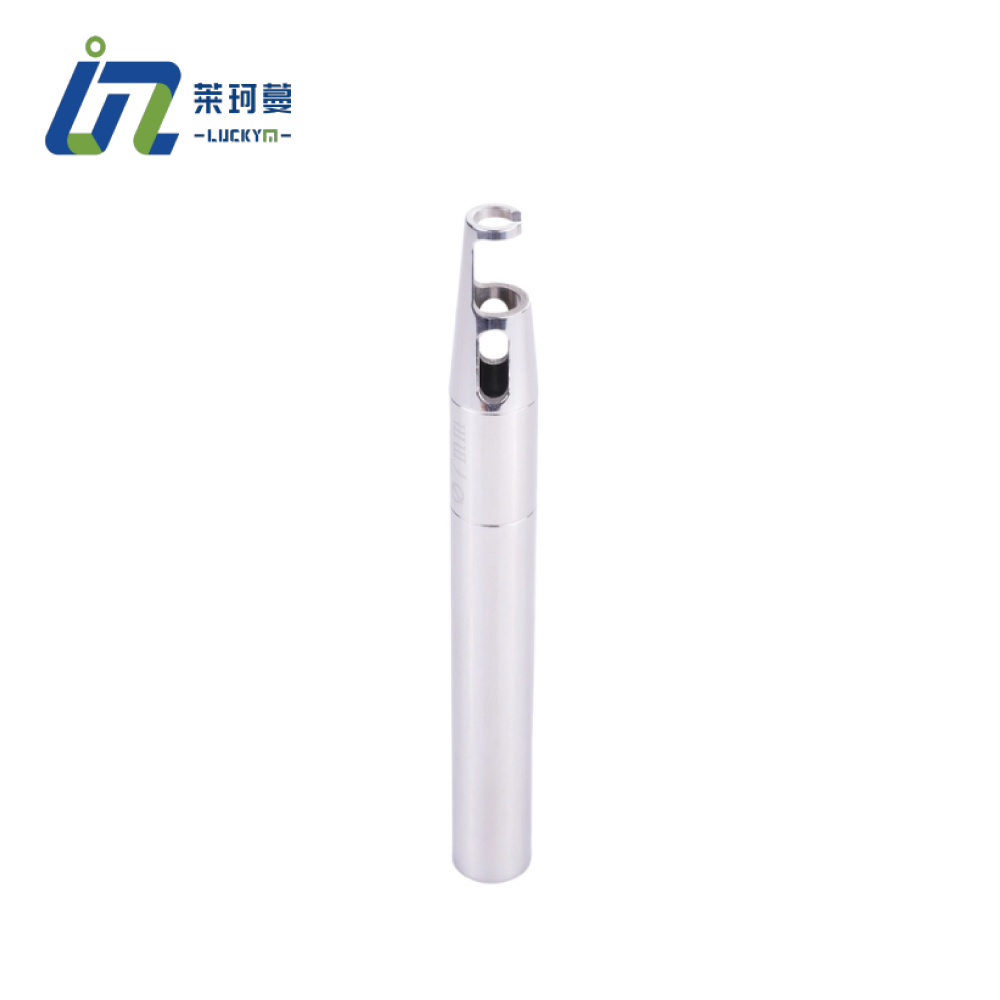

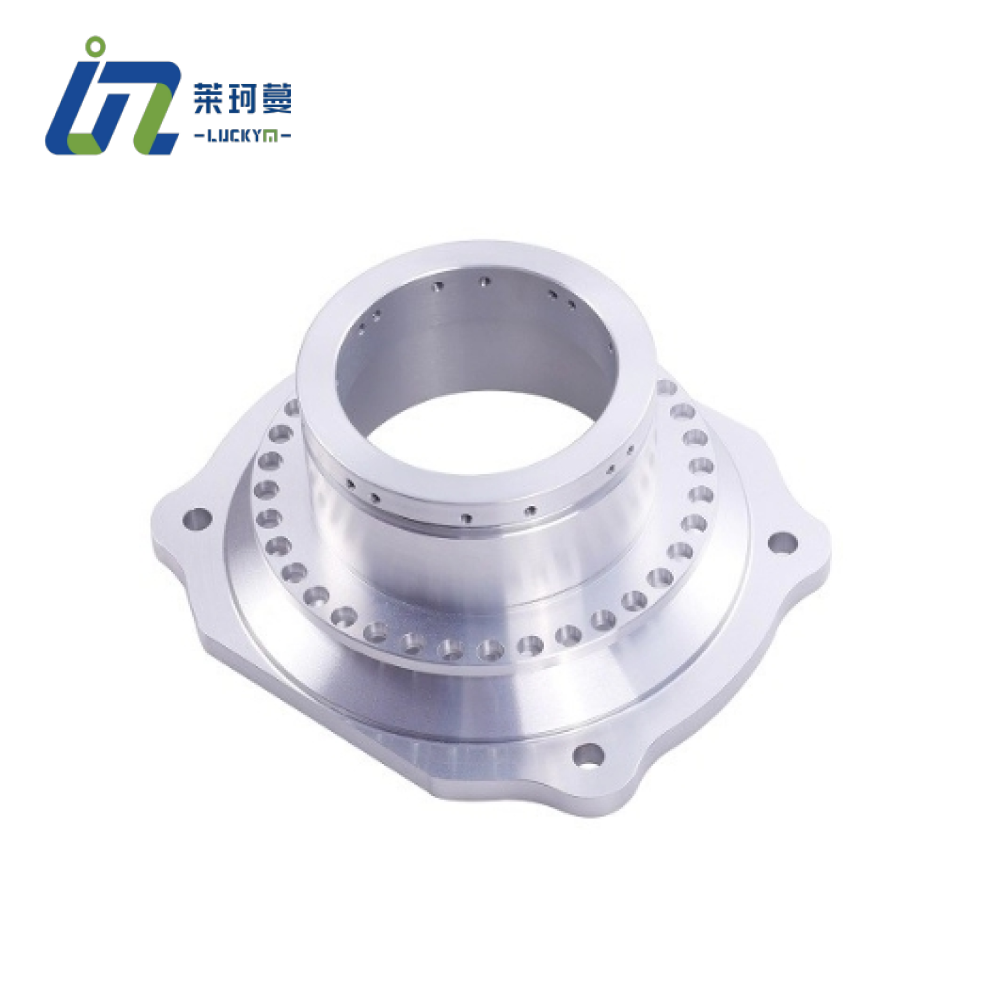

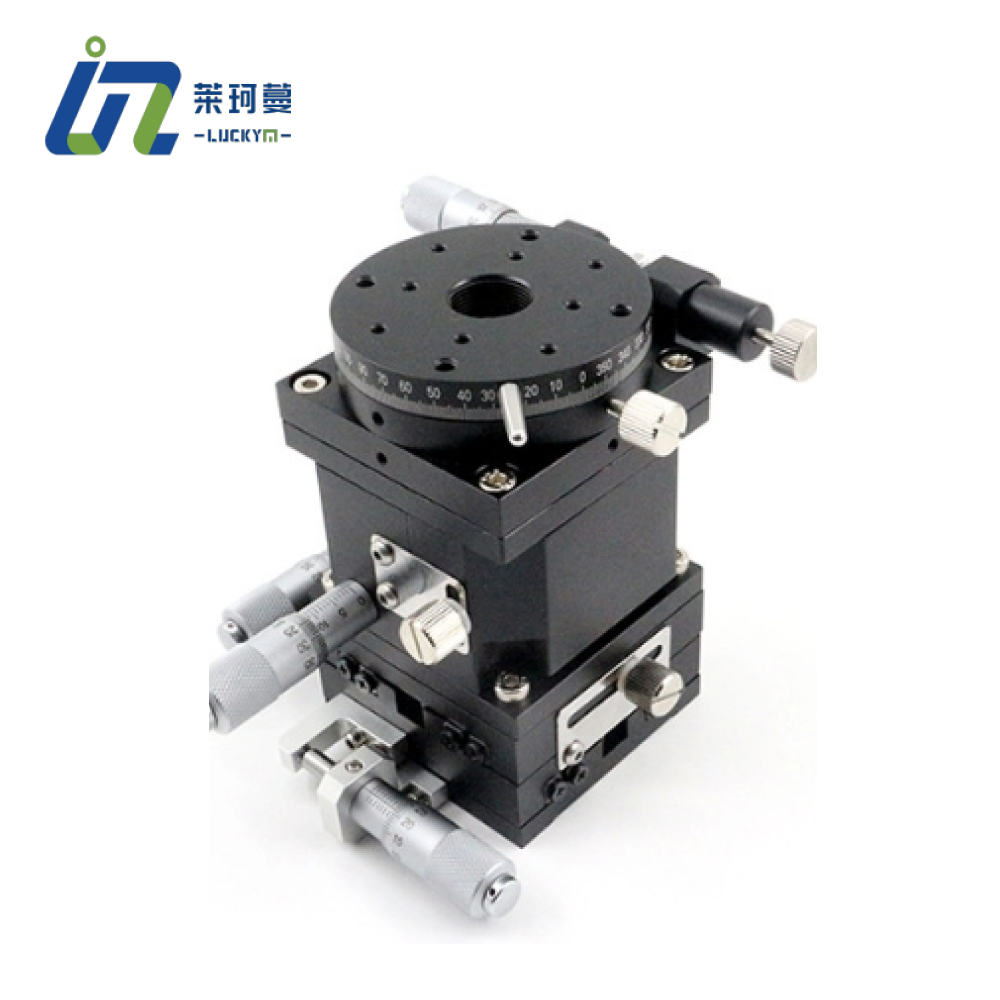

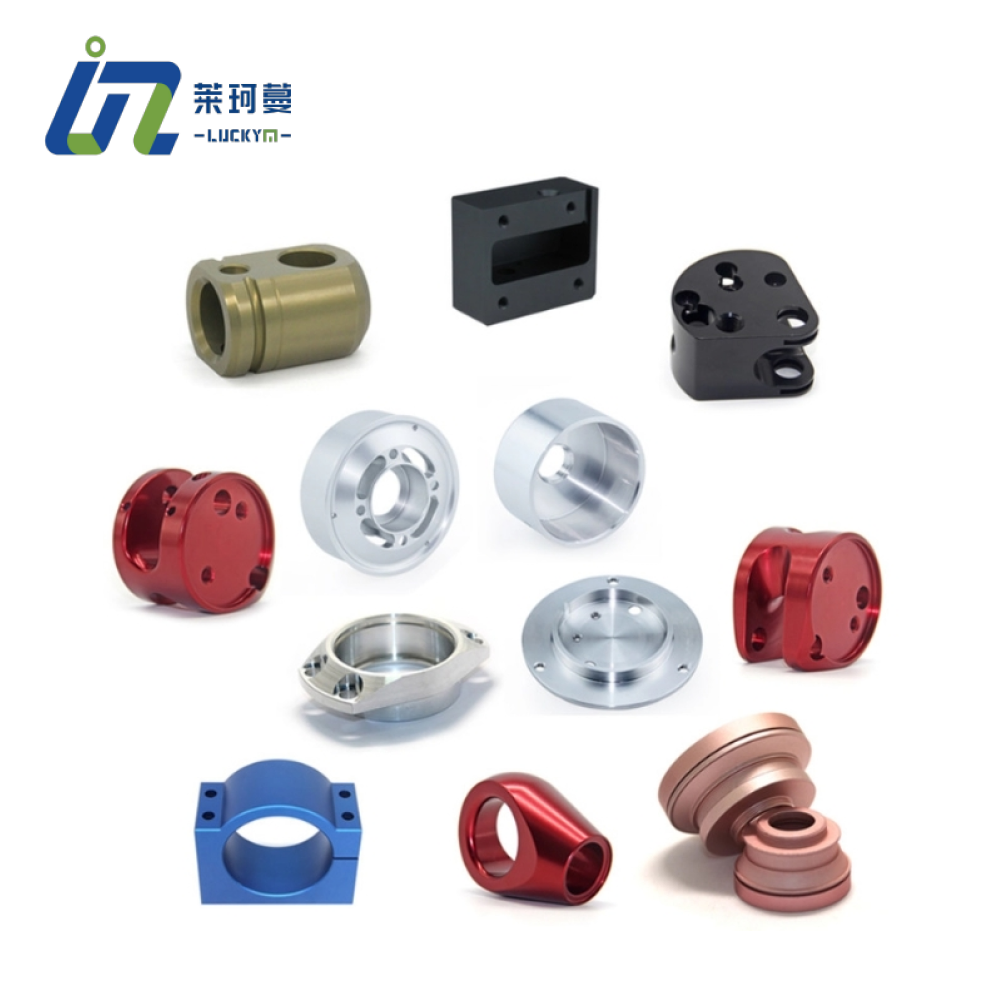

Gallery of Sheet Metal Fabrication parts

Craft for Sheet Metal Fabrication Parts

Sheet Metal Materials

Choose from a variety of sheet metal materials, each selected for its unique properties. This enables us to recommend the best options tailored to your project’s specific needs and applications.

Cold Rolled Sheet

Known as SPCC, cold rolled sheet is a widely used and highly common material in sheet metal processing. It is cost-effective and easy to form; however, it is prone to rusting.Galvanized Sheet

Also referred to as SECC or SGCC, galvanized sheet is a commonly used material in sheet metal processing. It offers corrosion resistance, is easy to form, and has a long service life, though it comes at a higher cost.

Beryllium Copper Plate

Beryllium copper plate is a resilient material known for its excellent electrical conductivity. It is fatigue-resistant and boasts a long service life, making it ideal for manufacturing high-demand components.

Stainless Steel Plate

Stainless steel is particularly well-suited for food-related machinery. Its high strength allows for reduced thickness in design. However, manufacturing stainless steel plates can be challenging, and they are prone to warping during the welding process.

Aluminum Alloy Plate

Aluminum alloy is a lightweight material that naturally forms an oxide layer on its surface to resist corrosion. These plates are widely utilized in various industries, including automotive, manufacturing, and renewable energy.Copper Plate

Copper plates offer excellent electrical and thermal conductivity, along with corrosion resistance and favorable processability. These characteristics make them ideal for wiring, motors, and other electrical applications.

Brass Plate

Brass is an alloy composed of copper and zinc. It possesses strong mechanical properties, making it commonly used in elastic components, hardware, and decorative materials.Steel

Steel is incredibly strong and durable, making it a common choice in construction and heavy industries. It can be alloyed with other elements to improve hardness or enhance corrosion resistance.

Surface Finishing Options for Metal Sheets

Boost the durability and aesthetics of your custom metal parts with our surface finishing options. If you have specific requirements, simply select “Get An Quote” and let us know what you need.

As Machined

A machined finish retains the surface as it comes directly from the CNC machine, offering a cost-effective option that may include tool marks.

Anodizing

Anodizing enhances corrosion resistance and wear properties while allowing for color dyeing, making it ideal for aluminum parts.

Polishing

Polishing produces a high-gloss finish, minimizing surface roughness and enhancing the visual appeal of metals.

Sand Blasting

Sand blasting employs pressurized sand or other media to clean and texture surfaces, resulting in a uniform, matte finish.

Brushed Finish

A brushed finish produces a unidirectional satin texture that minimizes the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a durable, wear-resistant layer available in a wide range of colors and textures, making it suitable for various surfaces.

Electroplating

Electroplating applies a thin metal layer to parts, enhancing wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

Black oxidizing is a conversion coating for ferrous metals that enhances corrosion resistance and reduces light reflection.

Electropolish

Electropolishing is a chemical process that creates a smooth, bright surface while also enhancing corrosion resistance.

Alodine

Alodine coating offers corrosion protection and enhances paint adhesion, primarily used on aluminum surfaces.

Ready to get started on your Sheet Metal Fabrication quote?

Start Your QuoteSheet Metal Fabrication for Various Industries

Our sheet metal fabrication service delivers custom, high-precision components for a variety of industries, emphasizing quality, durability, and dependable performance.

Aerospace

Automotive

Automation

Electronics

Robotics

Consumer goods

FAQs

How do I get started with my sheet metal project?

Step 1: Design Preparation

Begin by creating a detailed design of your part or component. If you’re uncertain about the specifications, our experienced engineering team is available to help you optimize your design for fabrication.Step 2: Upload Your Design

Next, upload your design files by submitting an inquiry through our website or contact us directly, including part specifications like material selection, thickness, and finishing options. After submission, you will receive a tailored quote based on your project’s requirements.Step 3: Fabrication Process

Once you confirm the quote, we will initiate the fabrication process. Our state-of-the-art machinery and skilled technicians guarantee precision and quality. We’ll keep you updated throughout the entire process, from manufacturing to the final delivery of your parts.How long does it take to receive my custom parts?

The lead time for your custom sheet metal parts varies based on factors such as part complexity, order quantity, and required fabrication processes. For straightforward parts, we can typically deliver within as little as 3 days after your order is placed and the design is confirmed.

For more intricate assemblies or larger orders, the production time will be longer. After you submit your design through our website, we will provide an estimated delivery timeline along with your quote. This estimate considers our current workload in the fabrication facilities and the specific needs of your project.

We aim to reduce turnaround time without sacrificing quality, ensuring you receive your parts as quickly as possible while upholding the highest fabrication standards.

How much does sheet metal fabrication cost?

The cost of sheet metal fabrication varies significantly based on factors such as part complexity, material type, order quantity, and specific fabrication processes. For simple parts, costs can be very competitive, particularly when utilizing our efficient production methods and advanced machinery.

For a specific cost estimate, we recommend submitting an inquiry through our website or contacting us directly to upload your design files. Please include details about materials, quantities, and surface finishing. Our engineering team will provide you with a detailed quote that accurately reflects the cost of your project.

For larger or more intricate orders, costs will be adjusted to account for the additional processing and labor involved. Our goal is to provide the best value by combining cost-effectiveness with high-quality results.

Is there a minimum order quantity for fabrication services?

We support projects of all sizes, accommodating both small and large production runs. Our services range from single prototypes to mass production, with no strict minimum order quantity. This flexibility enables customers, whether startups or large corporations, to utilize our sheet metal fabrication services tailored to their specific needs and scales.

What is the K factor in sheet metal?

The K factor in sheet metal fabrication is a key value that affects the accuracy of bend allowances when calculating the flat length of a sheet prior to bending. It represents the ratio of the neutral axis’s position to the material thickness. During the bending process, the inner surface of the metal compresses while the outer surface stretches, but the neutral axis remains unstressed.

Determining the correct K factor is essential, as it directly influences how much the sheet metal will stretch during bending. Generally, the K factor value ranges from 0.3 to 0.5, depending on the material and the bending method used. Accurate calculation of this factor ensures that the bent sheet metal parts fit precisely as intended, preserving dimensional integrity and functionality.

What is the difference between sheet metal and plate metal?

The main distinction between sheet metal and plate metal is their thickness and applications. Sheet metal is usually defined as thin, flat pieces ranging in thickness from approximately 0.006 inches to 0.25 inches. Because of its malleability, sheet metal is widely used in applications that require precise bending and shaping, such as automotive bodies, aircraft panels, and household appliances.

In contrast, plate metal is thicker, typically starting at 0.25 inches and extending to several inches. It is used in applications where durability and strength are paramount, such as in the construction of buildings, bridges, and heavy machinery. The thicker nature of plate metal makes it ideal for structural applications that require high strength and resistance to deformation.

Sheet Metal Fabrication Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Newsletter

Suspendisse a neque diam. Donec lacinia quam vitae tristique scelerisque. Nullam at tincidunt felis.

Check our latest Articles

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum se

We find your perfect property.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum sed.

Buy Your Dream Home

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum sed. Nibh aenean mattis nibh a semper urna.

Features

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum sed. Nibh aenean mattis nibh a semper urna.

Rent properties

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum sed. Nibh aenean mattis nibh a semper urna.

Testimonial

Get your Home Listed

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non.