OEM & Custom

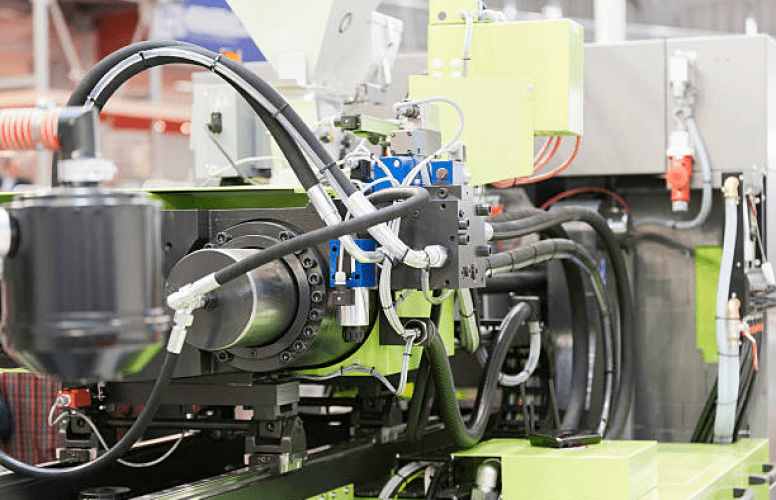

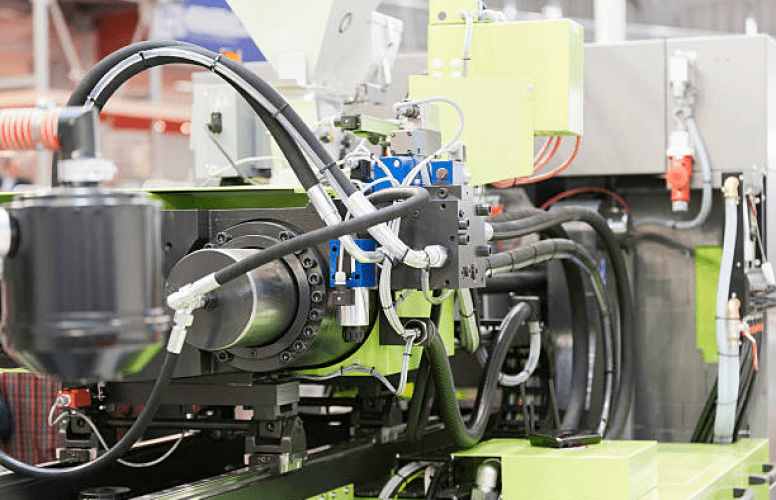

Injection Molding Service

Supplier in China

- Your Partner for Custom Plastic Parts, from Prototype to Production.

- Request a Free Quote: Get a fast, no-obligation quote for your injection molding project today.

- Receive Expert DFM Analysis: We provide a complimentary Design for Manufacturability analysis with every quote to ensure your design is production-ready.

- Certified Quality: Our operations are fully certified under ISO 9001:2015 (Quality) and ISO 14001:2015 (Environmental) standards.

Why Choose US for Custom Injection Molding Services

Plastic Injection Molding Services for Custom Parts

Experience a seamless design-to-production journey with our custom injection molding services. Whether you need rapid prototypes or high-volume production, we provide expert guidance and solutions. We work with a wide range of thermoplastics and thermosets and deliver parts with tolerances meeting or exceeding ISO 9001 standards.

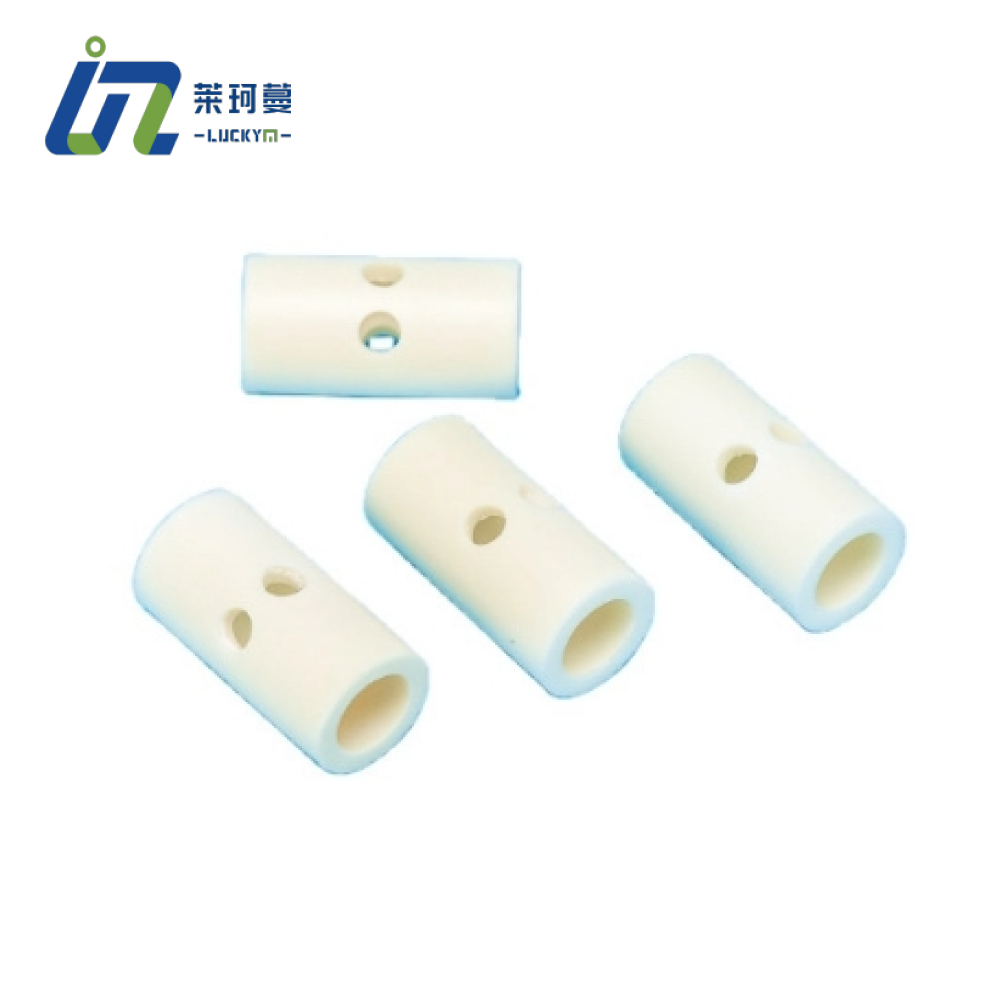

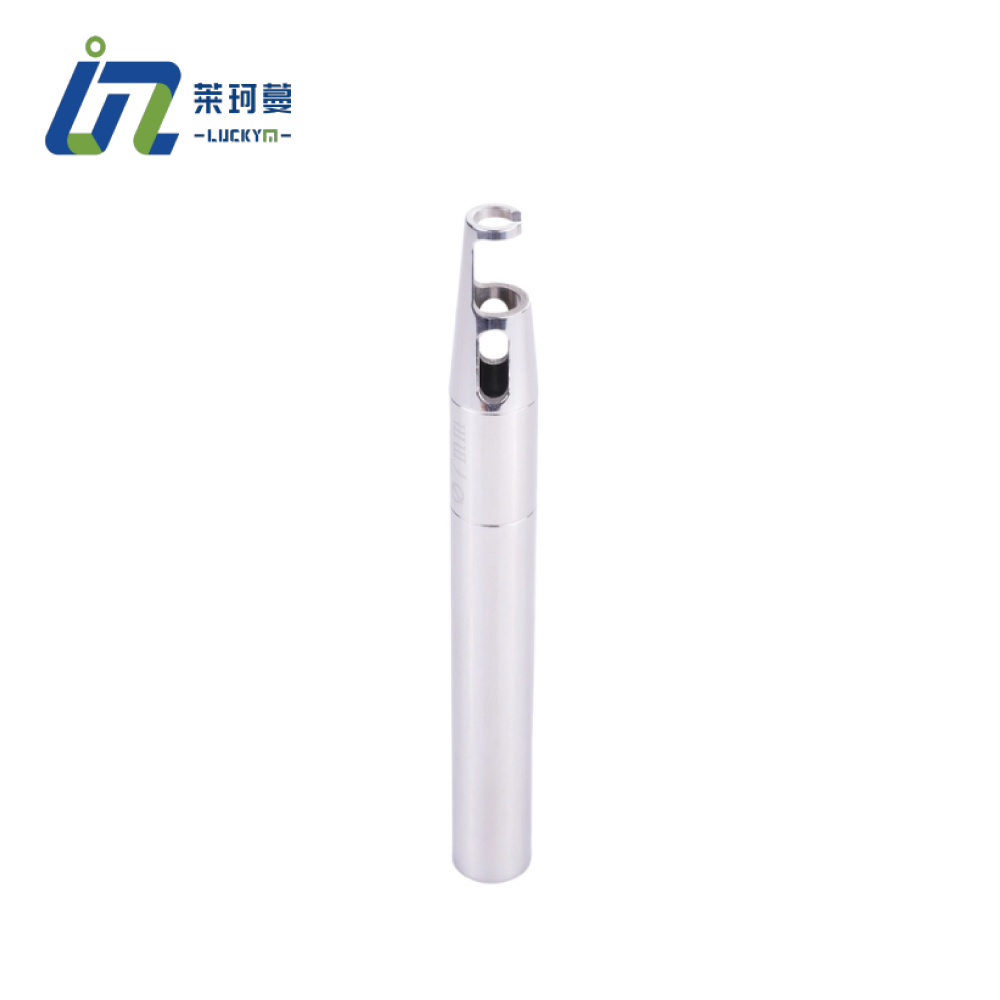

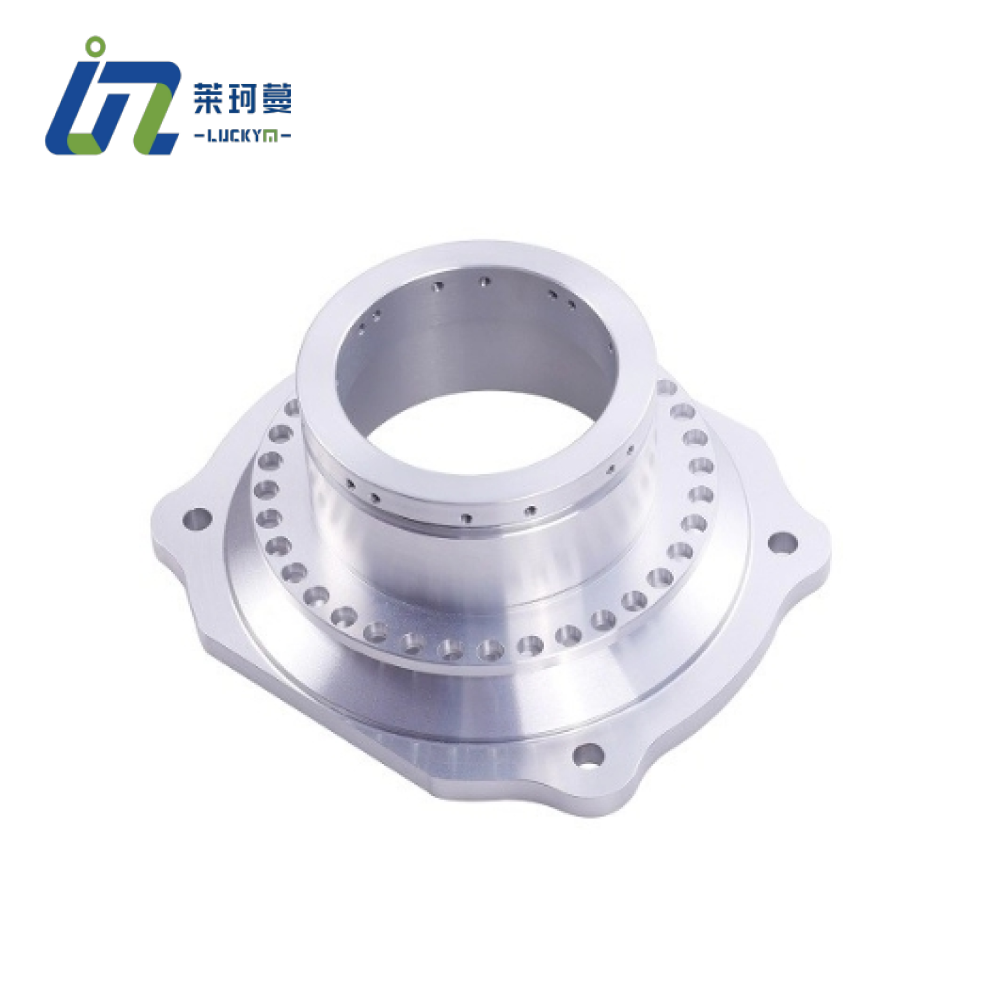

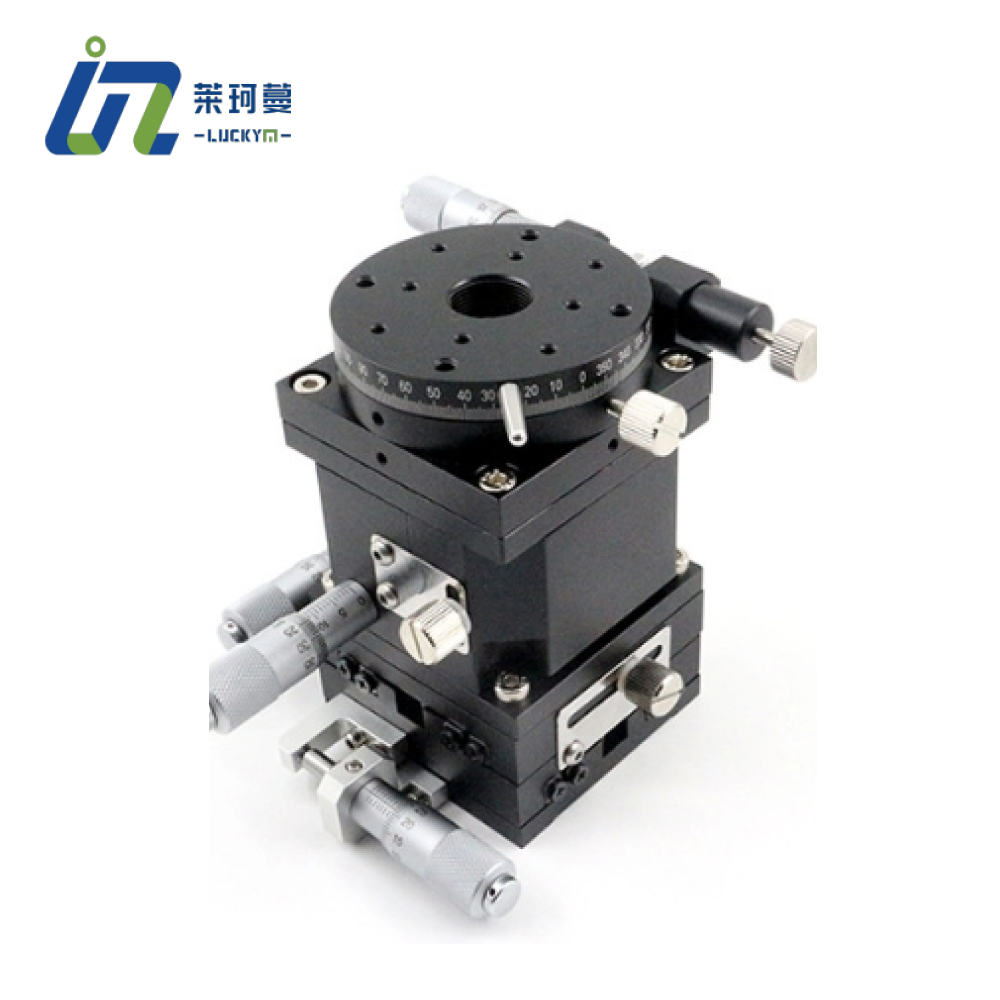

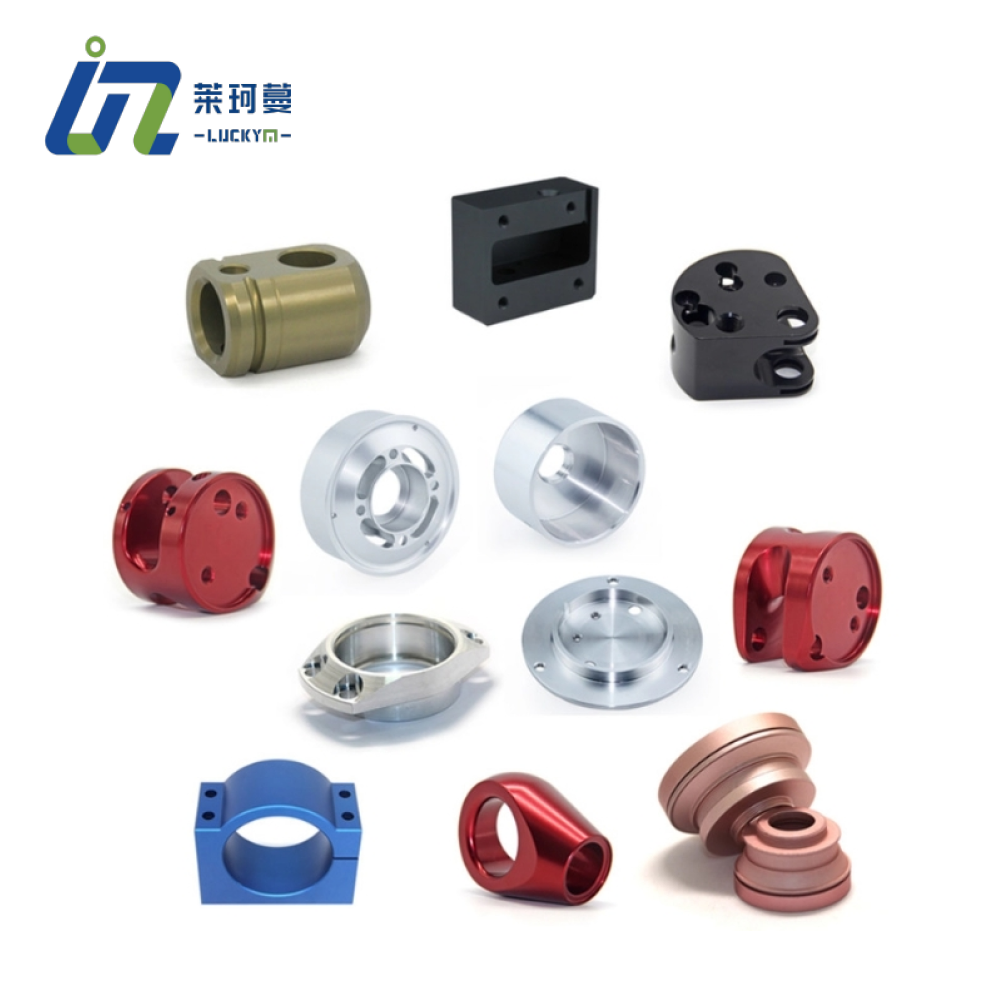

Gallery of Injection Molding parts

Injection Molding Materials

Plastic Injection Molding Materials

From durable thermoplastics to high-temperature thermosets, we provide a wide variety of materials. Each is selected to deliver the specific performance characteristics your application demands.

ABS

Count on the proven toughness and durability of ABS. Known for its exceptional impact and heat resistance, it’s the ideal choice for creating long-lasting parts in demanding fields like automotive, consumer electronics, and household appliances.

Color: Subtypes: ABS Beige (Natural), ABS Black, ABS Black Antistatic, ABS Milky White, ABS+PC Black, Flame Retardant ABS Beige, Flame Retardant ABS Black. PC

Polycarbonate (PC) is a high-performance thermoplastic distinguished by its exceptional impact strength and superior optical clarity. These properties make it the material of choice for applications where both durability and transparency are critical, such as in the manufacturing of ballistic-resistant glazing, ophthalmic lenses, and personal protective equipment.

Color: Subtypes: Flame Retardant Transparent PC, Food Grade PC-Transparent, PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black PMMA (Acrylic)

Achieve brilliant, long-lasting results with PMMA. Valued for its crystal-clear appearance and exceptional weather resistance, it’s the perfect choice for outdoor applications like signage, displays, and lighting fixtures. PMMA offers superior durability over glass and maintains its clarity and integrity even after prolonged UV exposure.

Color: Subtypes: PMMA Black, PMMA Transparent, PMMA White POM

Polyoxymethylene (POM) is an engineering thermoplastic valued for its high stiffness, excellent dimensional stability, and low coefficient of friction. These properties make it a superior choice for manufacturing high-precision mechanical components subjected to high stress, such as gears, bearings, and other close-tolerance parts.

Color: Subtypes: Dark Brown (Coffee) POM 100AF, POM Black, POM Blue, POM White PA (Nylon)

Rely on the proven durability of Nylon for your most demanding applications. This versatile material offers an exceptional blend of strength, flexibility, and wear resistance, ensuring long-lasting performance in high-friction environments. It’s the ideal choice for creating robust industrial parts like gears, bearings, and automotive components.

Color: Subtypes: PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black PE

Polyethylene(PE) is a lightweight but tough plastic that resists impacts well. It’s also resistant to chemicals, which makes it great for making things that are used outdoors or in wet conditions, like containers, pipes, and packaging.

Color: Subtypes: PE Black, PE White PEEK

PEEK: Unmatched performance under extreme conditions. Renowned for its superior heat resistance, chemical resistance, and mechanical strength, it is the premier material for critical components in the aerospace, automotive, and medical implant sectors where high performance is required.

Color: Subtypes: PEEK Beige (Natural) and PEEK Black PP

From resilient automotive components to safe medical devices and robust packaging, polypropylene(PP) is a highly adaptable material. Its combination of toughness, low weight, and excellent resistance to chemicals and moisture makes it a reliable and widely used solution across many industries.

Color: Subtypes: PP Black, PP White, PP+GF30 Black HDPE

From sturdy bottles and corrosion-proof piping to all-weather plastic lumber, High-Density Polyethylene (HDPE) is the material of choice for applications demanding resilience. Its excellent strength-to-density ratio and high impact resistance ensure durability in even the most challenging environments.

Color: Subtypes: HDPE Black, HDPE White HIPS

A versatile material valued for its ease of processing and good impact strength. With excellent dimensional stability, it’s the ideal choice for rapid prototyping, displays, and packaging where fast, easy molding is a priority.

Color: Subtypes: HIPS Board White LDPE

The go-to material for flexibility and sealing. Known for its soft, pliable nature and excellent sealing properties, it’s the industry standard for plastic bags, films, and flexible tubing where stretch and sealability are essential.

Color: Subtypes: LDPE White PBT

A strong, stable, and heat-resistant engineering plastic. Its rigidity and dimensional stability make it a great choice for high-performance automotive, electrical, and electronic components like connectors and housings.

Color: Subtypes: PBT Black, PBT Milky White(Natural) PET

PET is durable, chemically resistant, and moisture-resistant, making it suitable for a wide range of applications, including food containers, beverage bottles, and textiles. Its high strength and recyclability make it a popular choice for packaging.

Color: Subtypes: PET Black, PET White, PET+GF30 Black, PET+GF30 White PPS

PPS is a super-strong plastic that can handle very high heat and harsh chemicals without breaking down. This makes it perfect for making tough parts for cars, airplanes, and industrial machines that have to work in extreme environments.

Color: Subtypes: PPS Black, PPS White, PPS+GF30 Black, PPS+GF30 White PS

PS is lightweight and easy to process, making it a popular material for models, prototypes, and low-strength applications. Its ease of molding makes it a premier material for packaging and disposable items.

Color: Subtypes: PS Transparent PVC

PVC is a versatile, cost-effective material with excellent chemical resistance and durability. Due to its strength and versatility, PVC is widely used in pipes, medical devices, cables, and construction materials.

Color: Subtypes: PVC Grey PTFE (Teflon)

PTFE is known for its excellent chemical resistance and low friction properties and is commonly used in nonstick coatings, gaskets, seals, and bearings. It also performs well in extreme environments, such as high temperatures and corrosive chemicals.

Color: Subtypes: Teflon (PTFE) Black, Teflon (PTFE) White UPE

Extend the life of your high-wear equipment with UPE. This exceptionally tough and durable material provides unparalleled abrasion and impact resistance, making it the ideal solution for lining chutes, hoppers, and conveyor systems that are subjected to constant abuse.

Color: Subtypes: UPE Black, UPE White

Injection Molding Surface Finishing

| SPI Finish | Description | Typical Applications | Surface Roughness (Ra µm) |

| SPI A-1 | Grade #3, 6000 Grit Diamond Buff | High polish or transparent parts, optically clear | 0.012 – 0.025 |

| SPI A-2 | Grade #6, 3000 Grit Diamond Buff | High polish or transparent parts | 0.025 – 0.050 |

| SPI A-3 | Grade #15, 1200 Grit Diamond Buff | High-to-medium polish parts, non-optical lenses | 0.050 – 0.100 |

| SPI B-1 | 600 Grit Paper | Medium polish parts | 0.05 – 0.10 |

| SPI B-2 | 400 Grit Paper | Medium polish parts | 0.10 – 0.15 |

| SPI B-3 | 320 Grit Paper | Medium – low polish parts | 0.28 – 0.32 |

| SPI C-1 | 600 Stone | Low polish parts | 0.35 – 0.40 |

| SPI C-2 | 400 Stone | Low polish parts | 0.45 – 0.55 |

| SPI C-3 | 320 Stone | Low polish parts | 0.63 – 0.70 |

| SPI D-1 | Dry Blast Glass Bead | Satin finish | 0.80 – 1.00 |

| SPI D-2 | Dry Blast #240 Oxide | Dull finish | 1.00 – 2.80 |

| SPI D-3 | Dry Blast #24 Oxide | Dull finish | 3.20 – 18.00 |

Ready to get started on your CNC Machining quote?

Start Your QuoteInjection Molding Capabilities

| Standards | Description |

| Maximum Part Size | 1200×1000×500 mm |

| Manimum Part Size | 5×5×5 mm |

| Part to Part Repeatability | +/- 0.1 mm |

| Mold Cavities | Single-cavity molds, multi-cavity molds, family molds |

| Available Mold Types | Steel and aluminum molds. Production levels below 1000, 5000, 30000, and over 100000 uses |

| Mold Cavity Tolerances | +/- 0.02 mm |

| Secondary Operations | Mold texturing, pad printing, laser engraving, threaded inserts, and basic assembly |

| Undercuts | Y-type, L-type undercuts |

| Wall Thickness | 0.5 mm to 5 mm |

| Draft | 0.5° to 2° |

| Ribs/Gussets | 0.5 mm to 3 mm thick |

| Bosses | Diameter 3 mm to 10 mm |

| Lead Time | Most orders can be completed within 15 working days |

Applications of Injection Molding

Injection molding plays a vital role in the manufacture of a wide range of products—from automotive parts to medical devices. It’s highly efficient because it can produce large numbers of identical plastic parts to tight tolerances at a low cost per part. This is why many industries rely on it for large-scale production. Whether the design is simple or complex, it ensures high quality and fast production.

- Gears: Durable, high-tolerance gears for reliable mechanical and electronic performance.

- Housings: Robust protective housings for electronics, automotive and industrial equipment.

- Enclosures: Precision enclosures to safeguard internal sensitive electronic components.

- Handles: Ergonomic and durable handles designed for comfort and longevity on tools, appliances, and consumer products.

- Caps & Closures: High-quality caps and closures that ensure a secure, tight seal.

- Connectors: Intricate and reliable connectors for precise electronic applications.

Advantages of Injection Molding

Injection molding is essential when you need to manufacture complex parts with perfect consistency. Designed for high-volume production, it can produce millions of identical plastic parts with exceptional precision. While setup costs may be high, once you’re up and running, you can produce parts quickly and cost-effectively. Furthermore, its compatibility with a wide range of materials, including plastics and liquid silicone rubber, makes it the preferred choice for most plastic products on the market.

Disadvantages of Injection Molding

While plastic injection molding has many advantages, such as being well-suited for mass-producing complex parts, it also has some disadvantages. The main issues are high initial costs, long lead times, design limitations, and it’s not cost-effective for small batches. If these factors are crucial to your project, you may want to consider alternatives like 3D printing or CNC machining, which may be better suited to your needs.

FAQs

What is injection molding?

Die casting is a metal casting technique that involves forcing molten metal into a mold cavity under high pressure. The mold, known as a “die,” is made from two hardened tool steel components that are machined to shape, functioning similarly to an injection mold. Here’s how the process works:

1. Mold Preparation: The die is prepared and lubricated to ensure easy removal of the casting and to help control temperature.

2. Molten Metal Injection: Molten metal is injected into the die at high pressures, typically between 10 and 175 megapascals (1,500 to 25,000 psi). This pressure is maintained until the metal solidifies.

3. Cooling and Solidification: The molten metal cools rapidly within the mold, solidifying into the desired shape.

4. Ejection: After solidification, the die halves are opened, and the cast part is ejected.

5. Trimming: Any excess material from the casting, such as gates, runners, and flash, is trimmed away.

Die Casting Design Considerations?

When designing parts for die casting, several key factors must be considered to ensure optimal performance and manufacturability:

1. Wall Thickness: Maintain uniform wall thickness to promote even cooling and solidification, reducing the risk of defects like warping or internal stresses. While thinner walls allow for faster cooling and material savings, their feasibility depends on the metal used and the complexity of the part.

2. Draft Angles: Draft angles should be considered when designing so that the casting can be easily ejected from the mold. Typically, a draft angle of at least 1 to 2 degrees is required, depending on the depth of the part.

3. Fillets and Radii: Fillets and fillet radii are used to eliminate sharp corners and edges that can cause stress concentrations and crack initiation points. This adjustment also enhances the flow of molten metal within the mold.

4. Gating System: Design an efficient gating system to ensure that the molten metal flows smoothly into the mold, minimizing turbulence and air entrapment. The location of the gate affects material distribution and part quality.

5. Venting: Proper venting must be planned to remove air and gases from the mold cavity during metal injection, preventing issues like porosity and incomplete filling.

6. Simplifying Geometry: Simplify the geometry as much as possible to avoid undercuts and complex features that require intricate die mechanisms, which can increase tooling costs and complicate the casting process.

What is vibration in die casting?

In die casting, vibration refers to the mechanical vibrations that occur within the die casting machine and die.

Vacuum pressure casting: This process requires a vacuum to be created within the die cavity to minimize air entrapment and porosity. In this environment, vibrations can disrupt the vacuum, causing defects in the final product.

Low pressure casting: Metal is introduced into the die at low pressure, and the die is susceptible to vibrations, which can affect the steady flow of molten metal and affect the consistency and integrity of the casting.

Semi-solid die casting: Semi-solid metal is injected into the die. Vibrations can affect the thixotropy of the metal, which can affect the filling pattern and performance of the final part.

Squeeze die casting: This process applies additional pressure after the initial fill to increase the density and mechanical properties of the casting. Vibrations at this stage can cause uneven pressure application, resulting in inconsistent casting quality.

What is the manufacturing cycle for die casting tools?

The manufacturing cycle for die casting molds is typically 2 to 12 weeks. This cycle starts from the initial design stage (part concept development and specification formulation) and continues until the mold is completed. The complexity of the part design, the specific metal selected for casting, and the precision required for the final product can significantly affect the duration of the mold manufacturing process. In addition, once the mold is machined, it needs to be rigorously tested to ensure that it meets quality standards. Any necessary adjustments or modifications to the mold to correct defects or improve functionality will increase the total lead time. Effective communication between the manufacturing team and the customer is essential to streamline the process and meet production deadlines.

What are the tolerances for die casting?

Die casting is a precision manufacturing process that is capable of very tight tolerances, making it ideal for producing complex, high-volume parts. In general, die casting tolerances depend on part size, the metal used, and the specific casting process. Tolerances for standard sizes range from ±0.1 mm (less than 25 mm) to ±0.5 mm (up to 250 mm). More precise tolerances as low as ±0.02 mm can be achieved through additional post-machining processes.

The material also plays a crucial role in defining tolerances. Metals such as aluminum and zinc alloys have different shrinkage and mechanical properties, which can affect the final dimensional accuracy. Advanced die casting techniques such as vacuum casting or squeeze casting can further enhance tolerance control by reducing porosity and improving the integrity of the metal.

Can you post-process die castings?

Yes, post-processing of die castings is not only possible, but often necessary to achieve precision and surface finishes that are not achievable with die casting alone. Post-processing allows for tighter tolerances and smoother surfaces, which are essential for high performance and aesthetics. Common post-processing processes include drilling, milling, and CNC machining, which can refine features on die castings to exact specifications.

In addition, post-processing can correct any minor defects that occurred during the casting process, such as porosity or surface imperfections. It can also add complex features and fine details that are not achievable with casting alone. By combining die casting with post-processing, manufacturers can leverage the speed and cost-effectiveness of die casting to achieve the blank shape while achieving the accuracy of CNC machining to achieve critical dimensions and surface finish.

Looking to buy Your Next Dream Home?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna.

Buy home

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Proin in sapien vitae mi mollis sollicitudin.

Buy Your Dream Home

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum sed. Nibh aenean mattis nibh a semper urna.

Contact one of our agents today!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Arcu, porttitor nisi faucibus lorem urna. Condimentum risus non magna tortor elementum sed. Nibh aenean mattis nibh a semper urna.

For inquiries contact:

Paris Zhang

Rental Properties Manger

(+41) 9482-2931

[email protected]

Get in contact with one of our representatives today.