Top Die Casting: Your Guide to Aluminum & Custom Die Casting Firms

Summary

Discover the world of die casting and how leading die casting companies deliver high-quality aluminum and zinc parts for industries worldwide.

This article is your go-to resource for understanding die casting services, the die casting process, and how to choose the right partner for your next die casting project. Whether you’re new to die casting or looking to optimize your manufacturing, you’ll find practical insights, expert tips, and real-world examples to help you succeed.

What Is Die Casting and Why Is It So Important?

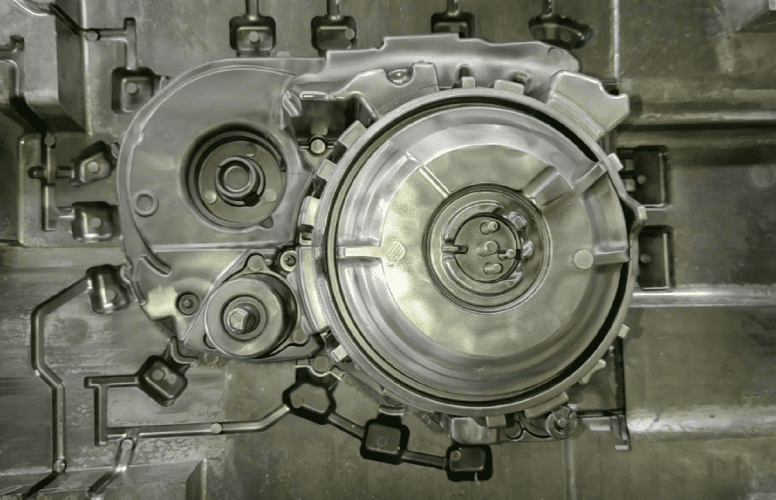

Die casting is a manufacturing process where molten metal is forced into a mold cavity under high pressure. This process creates strong, precise, and complex metal parts quickly and efficiently. Die casting is essential in industries like automotive, aerospace, electronics, and consumer goods because it allows for mass production of high-quality components with excellent surface finishes and tight tolerances

Why is this article worth reading?

If you’re involved in product design, engineering, or manufacturing, understanding die casting can help you make better decisions about materials, processes, and suppliers. You’ll learn how die casting companies deliver reliable solutions, what makes aluminum die casting so popular, and how to ensure your die cast parts meet the highest standards.

How Does the Die Casting Process Work?

The die casting process starts with melting a metal—often aluminum, zinc, or magnesium—until it becomes a liquid. This molten metal is then injected into a steel mold, called a die, using a die casting machine. The metal cools and solidifies quickly, taking the exact shape of the mold. Once solid, the die cast part is ejected, and the process repeats

Key Steps in the Die Casting Process:

| Step | Description |

|---|---|

| Mold Preparation | The die is cleaned and preheated to prevent defects. |

| Injection | Molten metal is injected into the die at high pressure. |

| Cooling | The metal cools and solidifies in the mold. |

| Ejection | The finished part is ejected from the die. |

| Trimming | Excess material is removed from the casting parts. |

Why is this process so effective?

Die casting allows for the rapid production of thousands—or even millions—of identical parts. The high pressure ensures that every detail of the mold is captured, resulting in precise, high-quality components

What Are the Main Types of Die Casting?

There are several types of die casting, each suited to different materials and applications. The most common are:

- Hot Chamber Die Casting: Used for metals with low melting points, like zinc and magnesium. The metal is melted inside the casting machine, allowing for fast cycles and high production rates

- Cold Chamber Die Casting: Used for metals with higher melting points, such as aluminum. The metal is melted in a separate furnace and then ladled into the casting machine. This method is ideal for aluminum die casting and magnesium die casting

- Gravity Die Casting: Relies on gravity to fill the mold, reducing air entrapment and energy use

- Vacuum Die Casting: Uses a vacuum to remove air from the mold, improving surface finish and reducing porosity.

- Squeeze Die Casting: Combines high pressure and low pressure to create dense, high-quality parts with minimal porosity

Table: Comparison of Die Casting Types

| Type | Best For | Key Benefits |

|---|---|---|

| Hot Chamber | Zinc, Magnesium | Fast, efficient, low melting point |

| Cold Chamber | Aluminum, Copper | Stronger metals, larger parts |

| Gravity | Aluminum, Zinc | Simple, less air entrapment |

| Vacuum | Aluminum, Zinc | Superior finish, less porosity |

| Squeeze | Aluminum, Magnesium | High strength, dense parts |

Why Choose Aluminum Die Casting for Your Project?

Aluminum die casting is one of the most popular choices for manufacturing lightweight, strong, and corrosion-resistant parts. Here’s why so many industries rely on aluminum die casting:

- Lightweight and Durable: Aluminum offers an excellent strength-to-weight ratio, making it perfect for automotive and aerospace applications where reducing weight is crucial

- Corrosion Resistance: Aluminum naturally resists rust and corrosion, ensuring long-lasting parts even in harsh environments

- Thermal and Electrical Conductivity: Aluminum is a great conductor of heat and electricity, making it ideal for electronic housings and heat sinks

- High Precision and Surface Finish: The die casting process produces parts with tight tolerances and smooth surfaces, reducing the need for extra machining

- Cost-Effective for High Volumes: Aluminum die casting is efficient and economical for large production runs, thanks to reusable molds and rapid cycle times

Common Applications:

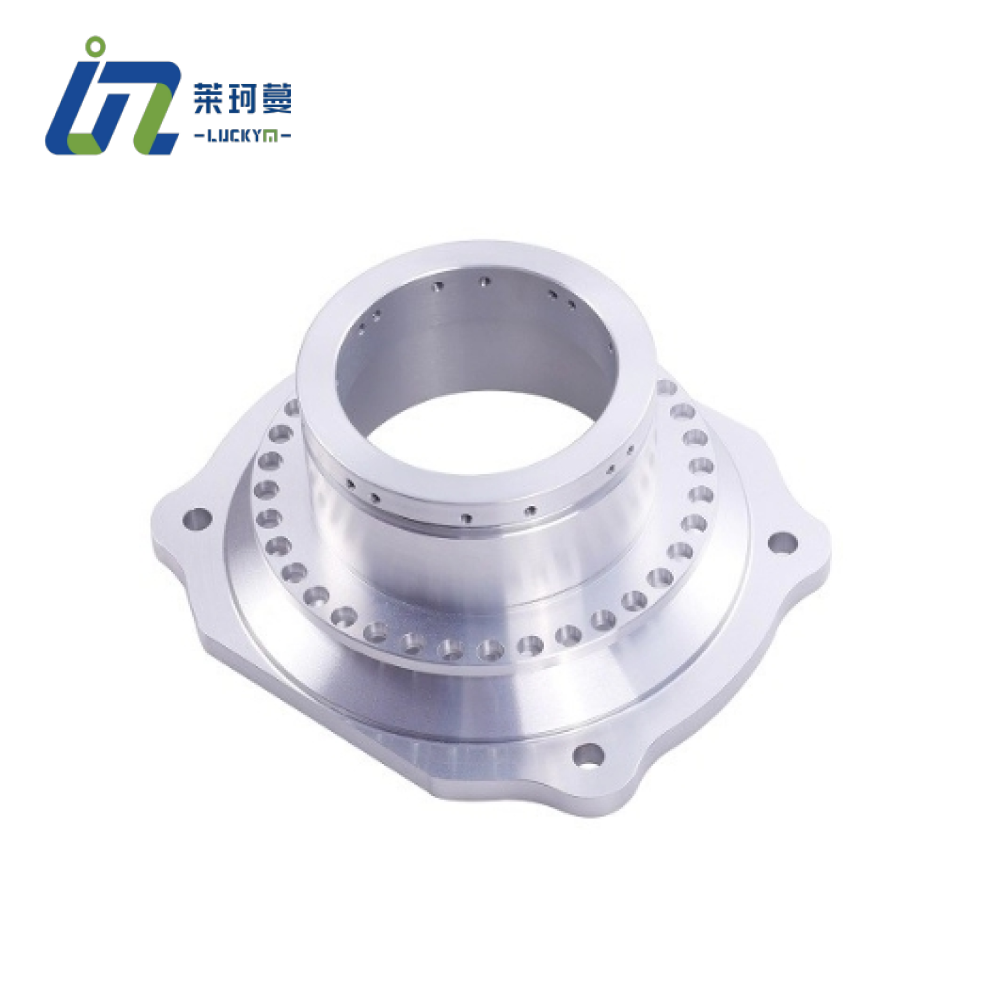

- Engine blocks, transmission housings, and wheels in the automotive industry

- Structural components in aerospace

- Electronic enclosures and connectors

- Appliance housings and power tool bodies

Comparing Die Casting Materials: Aluminum, Zinc, and Magnesium

Choosing the right material for your die casting project is essential. Here’s a quick comparison of the most common die casting materials:

| Material | Strength | Weight | Corrosion Resistance | Cost | Best For |

|---|---|---|---|---|---|

| Aluminum | High | Light | Excellent | Moderate | Automotive, aerospace, electronics |

| Zinc | Medium | Medium | Good | Low | Small parts, decorative hardware |

| Magnesium | Medium | Very Light | Good | Higher | Electronics, automotive, medical |

Aluminum:

Best for lightweight, strong, and corrosion-resistant parts. Used in automotive, aerospace, and electronics

Zinc:

Offers high precision, durability, and a lower melting point, making it cost-effective for high-volume production. Great for small, intricate parts and decorative hardware

Magnesium:

The lightest of the three, magnesium is perfect for applications where weight is critical, such as electronics and medical devices. It’s also easy to machine

Tip:

Consider the specific needs of your die casting project—such as strength, weight, cost, and environmental exposure—when choosing between aluminum, zinc, and magnesium

How Do Die Casting Companies Ensure Quality Control?

Quality control is at the heart of every successful die casting service. Leading die casting companies use a range of techniques to ensure every die cast part meets strict standards for strength, accuracy, and appearance.Key Quality Control Steps:

- Design Phase: Quality starts with careful planning. Engineers use control plans, dimensions, and FMEA (Failure Mode and Effects Analysis) to identify and prevent potential issues

- Sampling and Testing: Before full production, sample parts are made and tested for function, dimensions, and appearance. Clients often review and approve these samples.

- Production Monitoring: During production, operators use control sheets to track each batch. They measure and test the first parts, check packaging, and perform regular inspections.

- Advanced Inspection: Technologies like CNC coordinate measuring machines, X-ray, and ultrasonic testing help detect internal flaws and ensure dimensional accuracy

- Material and Mold Checks: Raw materials are tested for purity, and molds are inspected regularly to prevent defects.

- Temperature Control: Keeping the right temperature is crucial for consistent metal flow and cooling

Benefits of Quality Control:

- Fewer defects and less waste

- Lower costs due to early detection of problems

- Longer-lasting, more reliable parts

- Higher customer satisfaction

Quote:

“Accurate controls at every stage of the die-casting process help reduce non-compliances and ensure high-quality results.”

What Are the Capabilities of Modern Die Casting Machines?

Modern die casting machines are powerful, precise, and versatile. They can produce everything from tiny electronic connectors to large automotive parts.Capabilities Include:

- High Pressure: Machines can inject molten metal at pressures over 10,000 psi, ensuring every detail of the mold is filled

- Complex Geometries: Advanced machines can create intricate shapes and thin walls that would be impossible with other methods.

- Large and Small Parts: Die casting machines come in various sizes, allowing for the production of both small and large casting parts.

- Automation: Many die casting companies use robots and automated systems for loading, unloading, and quality checks, increasing speed and consistency.

- CNC Machining Integration: Some facilities offer CNC machining as a secondary operation, allowing for even tighter tolerances and more complex features.

Table: Die Casting Machine Features

| Feature | Benefit |

|---|---|

| High-pressure injection | Precise, detailed parts |

| Automated handling | Faster production, fewer errors |

| Multiple cavities | Produce several parts at once |

| Real-time monitoring | Immediate detection of issues |

News & Blog

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Top Die Casting: Your Guide to Aluminum & Custom Die Casting Firms

Discover the world of die casting and how leading die casting companies deliver high-quality aluminum and zinc parts for industries…

Precision Unlocked: Your Guide to CNC Machining & Machines

Are you curious about how everyday products—from cars to smartphones—are made with such incredible accuracy? This article dives deep into…Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

Newsletter

Suspendisse a neque diam. Donec lacinia quam vitae tristique scelerisque. Nullam at tincidunt felis.