OEM & Custom

Wire EDM Machining Services

Supplier in China

Obtain precision wire EDM parts with exceptional accuracy and complexity, perfect for complex geometries that require the highest standards. We are ISO 9001:2015 and ISO 14001:2015 certified.

Why Choose US for Wire EDM Machining Services

What is Wire EDM?

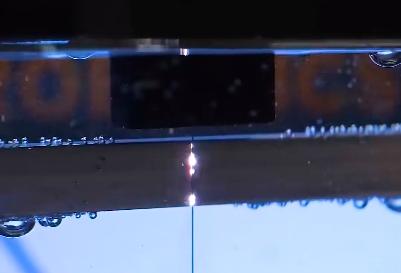

Wire EDM(Electrical Discharge Machining) is a precision manufacturing process that utilizes electrical discharges to cut conductive materials with exceptional accuracy. A thin, electrically charged wire serves as the cutting tool, allowing for the machining of intricate shapes and tight tolerances that traditional methods cannot achieve.

The true strength of wire EDM is its capability to machine complex contours and intricate details in materials that are often difficult to process with traditional CNC machining. This includes heat-treated steels, superalloys, and other specialized metals. With wire EDM, we can produce parts with exceptionally tight tolerances and fine features, such as narrow slots and small holes, with unmatched accuracy.

Our wire EDM services are ideally suited for applications that demand exacting precision. Whether producing components for aerospace, automotive, or complex molds and dies, our technology guarantees every cut is precise and of the highest quality. Our dedication to precision and quality is supported by advanced wire EDM equipment and a team of skilled technicians who are experts in their field. This combination positions us as a leader in wire EDM machining, enabling us to deliver parts that meet the stringent requirements of any industry.

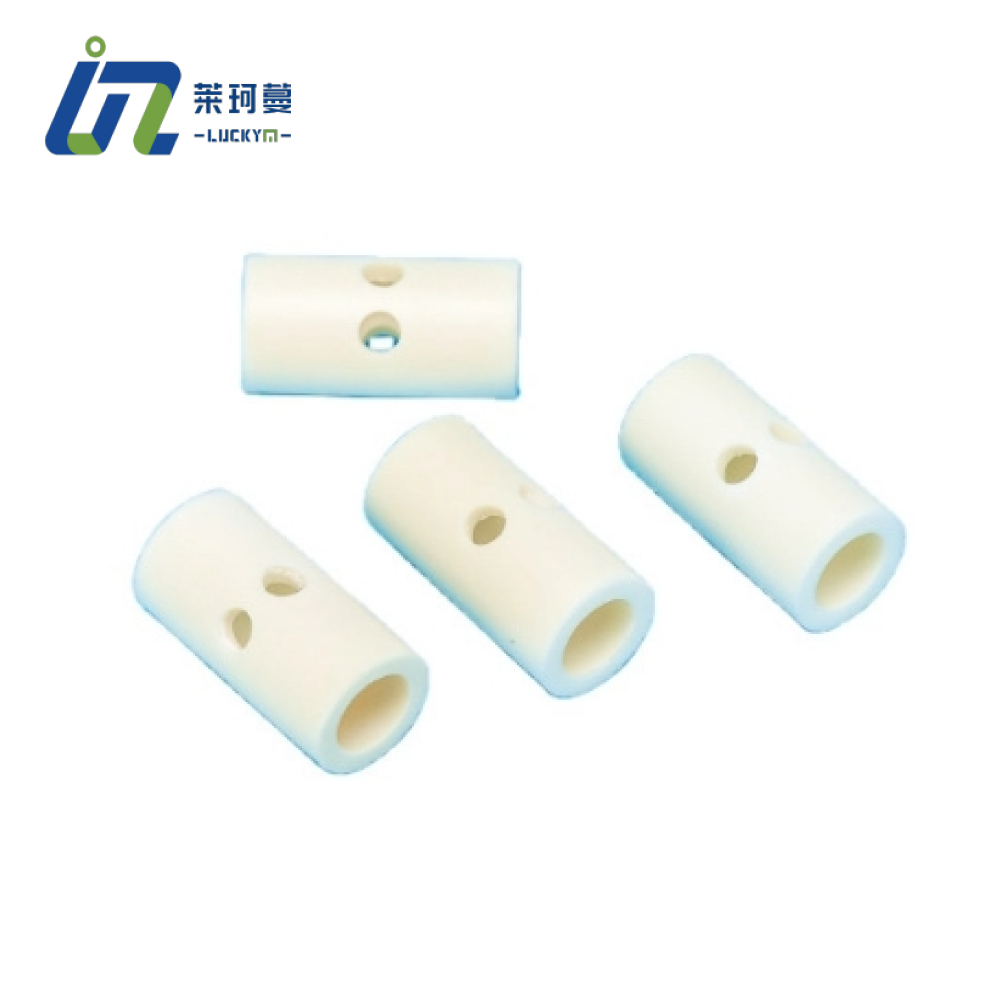

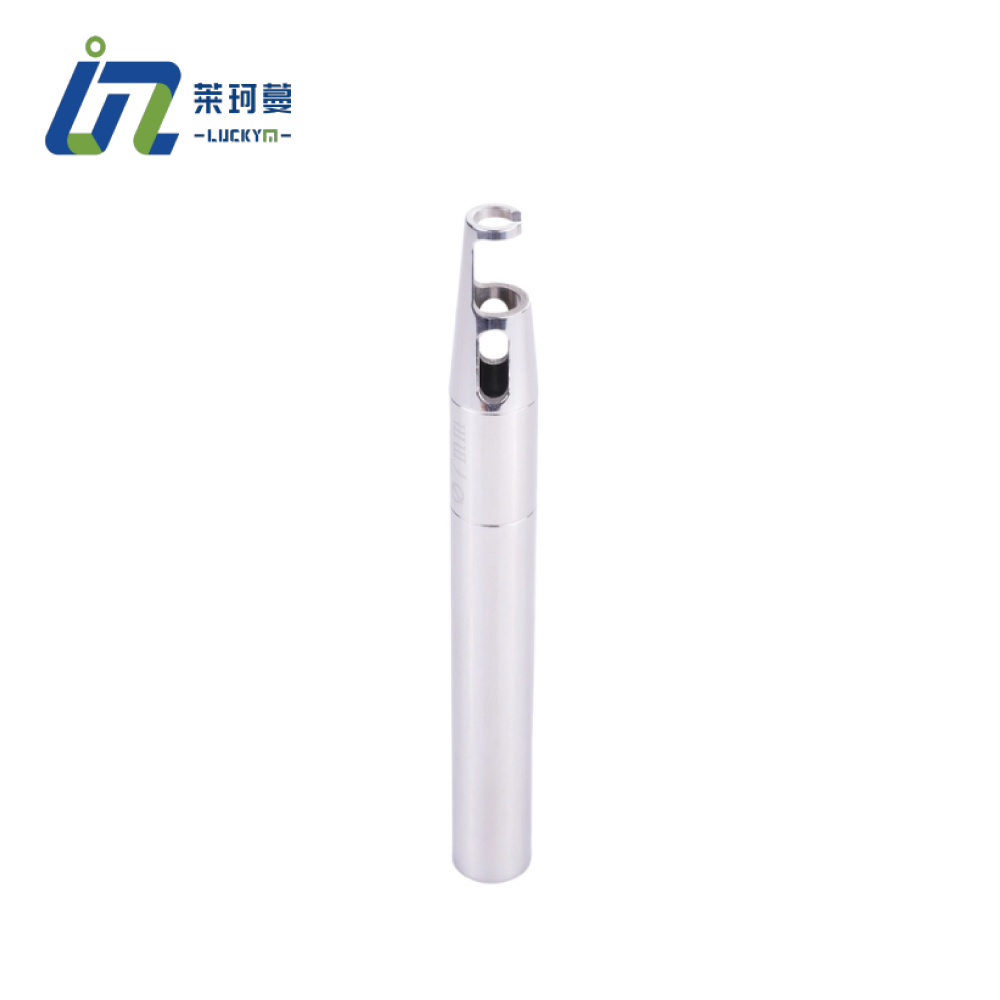

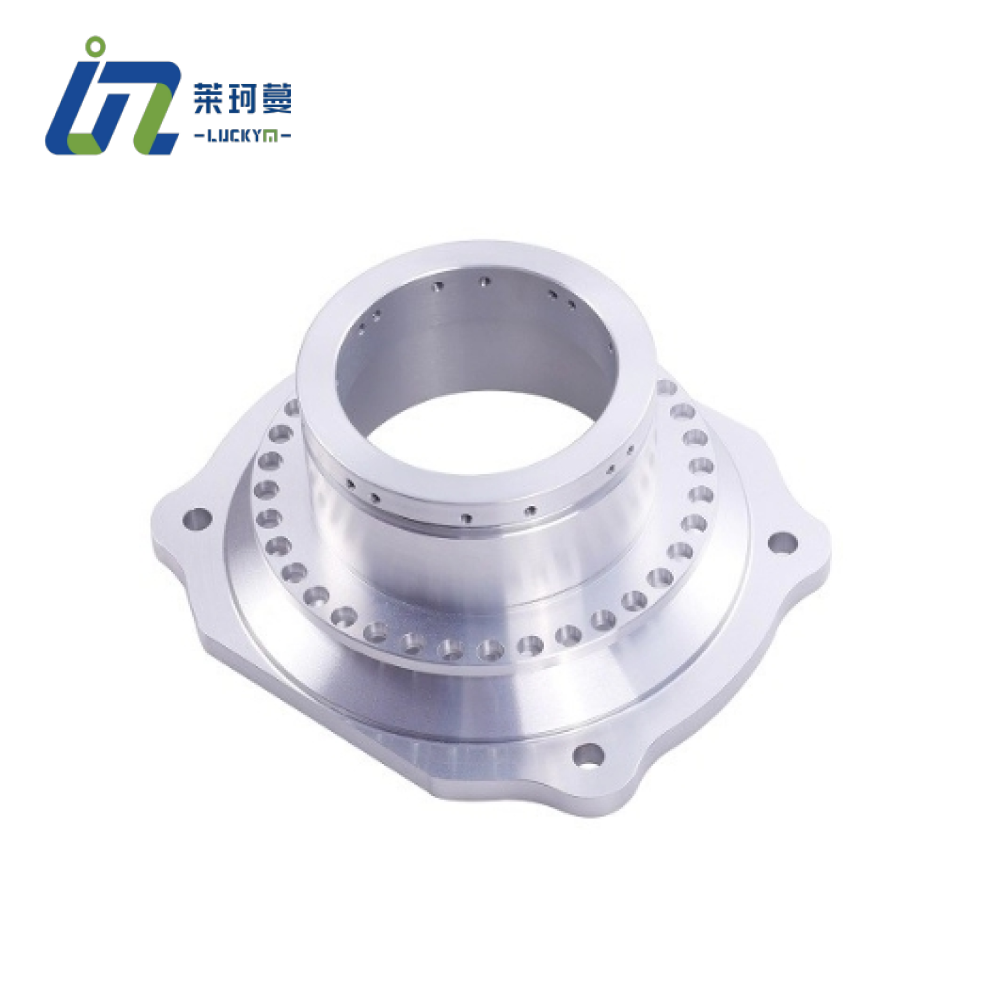

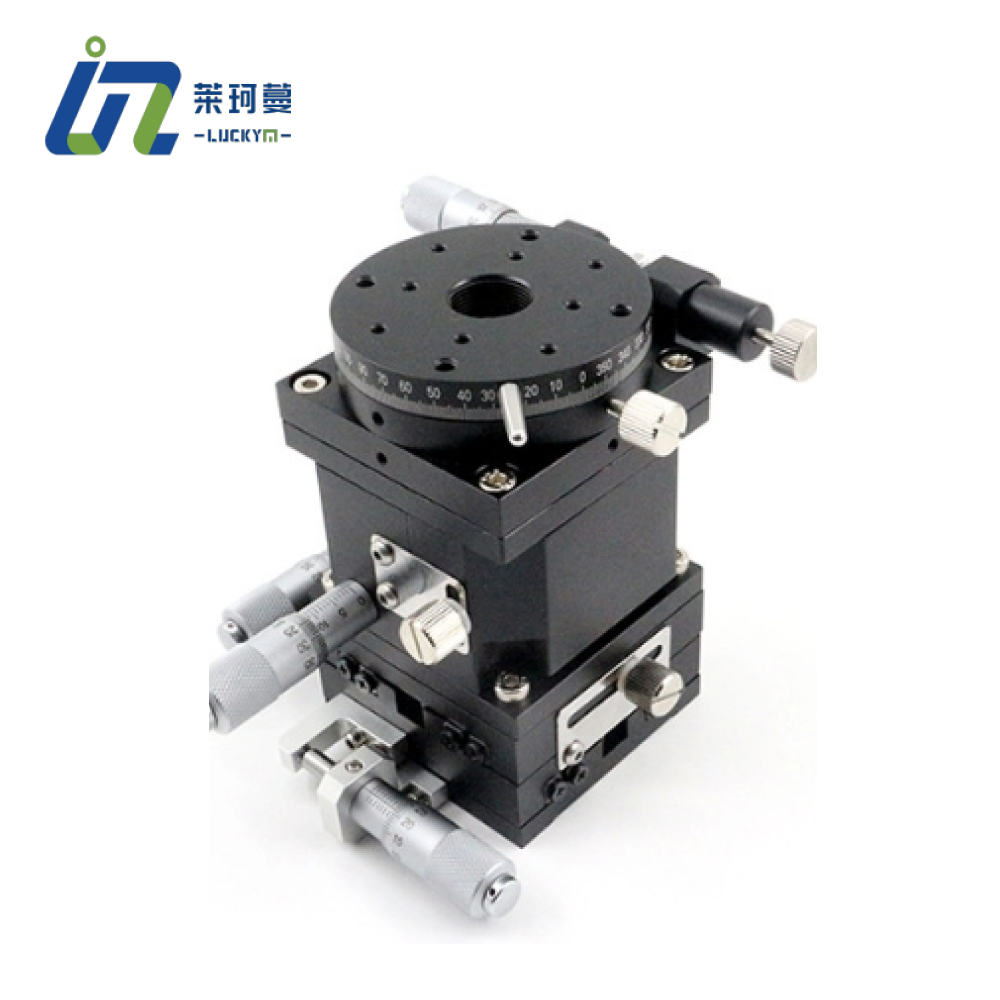

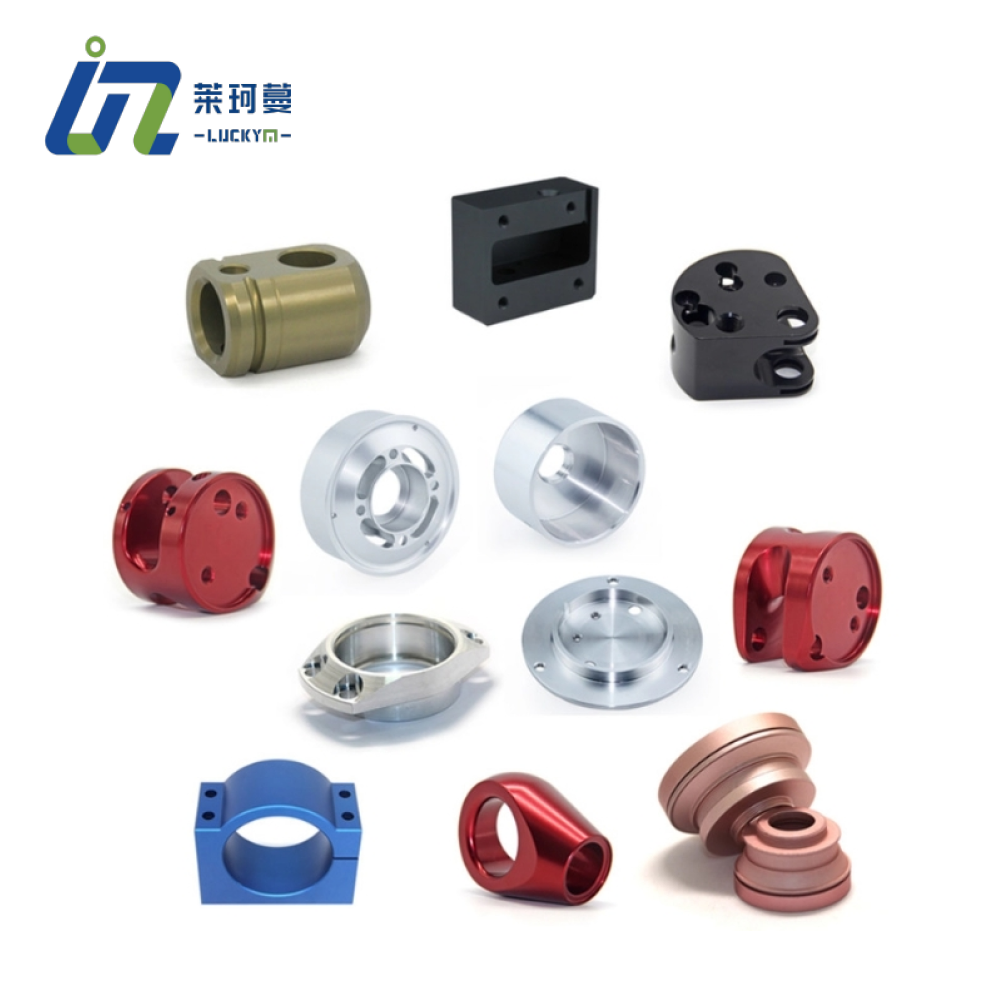

Gallery of Wire EDM Parts

How Wire EDM Machining Works

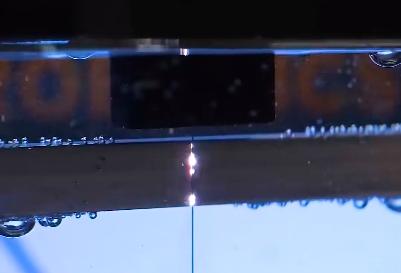

In wire EDM machining (Wire Electrical Discharge Machining), a thin wire is precisely controlled and guided by computer systems as it moves through a workpiece submerged in deionized water. This wire serves as both a guide and electrode, utilizing electrical discharges to accurately cut conductive materials, resulting in parts with finely finished surfaces that typically require minimal further processing. Our state-of-the-art facilities guarantee that even the most complex designs are executed with precision, reflecting our commitment to quality and client satisfaction.

Step 1 Prepare the Workpiece

The first step involves securely clamping the workpiece onto the EDM machine’s worktable to keep it stationary. Next, the surface is thoroughly cleaned and degreased to eliminate any contaminants. It is essential that the workpiece material is conductive, as wire EDM relies on a conductive medium to operate effectively.Step 2 Establish the Electrical Discharge

Next, a thin metal wire is passed through the machine’s guides, and both the wire and workpiece are submerged in a dielectric fluid, typically deionized water. An electrical potential is applied, causing the fluid to break down and generating an electrical discharge (spark) that erodes the surface of the workpiece.

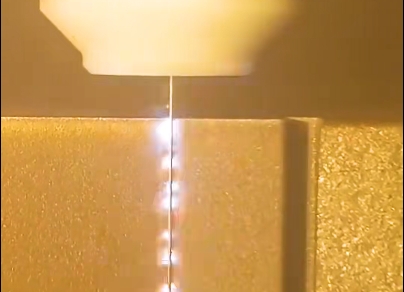

Step 3 Control the Wire Movement

The final step involves precisely controlling the wire’s movement with a computer numerical control (CNC) system. The CNC guides the wire along a predetermined path, allowing it to cut complex shapes and profiles in the workpiece. The dielectric fluid is continuously circulated to remove debris and regulate temperature during the cutting process. Once the cutting is complete, the workpiece is removed, resulting in a high-quality, precisely machined part.

Wire EDM Materials

The materials suitable for Wire EDM processing must generally be electrically conductive. Our Wire EDM services effectively machine a diverse array of conductive materials, including tough superalloys and hardened steels, ensuring the production of precise and durable components for demanding industries.

Stainless Steel

Stainless steel provides exceptional corrosion resistance and strength, making it an ideal choice for durable, long-lasting components across various industries, including medical and food processing.304: Widely used for its corrosion resistance and strong mechanical properties.316: It offers superior corrosion resistance, particularly in chloride environments.420: It is known for its high hardness and wear resistance, making it a popular choice for cutlery.17-4 PH: It is a precipitation-hardened steel known for its high strength and good corrosion resistance.Titanium Alloys

Titanium offers an outstanding strength-to-weight ratio and excellent biocompatibility, making it ideal for aerospace applications and medical implants that demand both durability and lightweight characteristics.

Ti-6Al-4V: It features a high strength-to-weight ratio and exceptional corrosion resistance, making it widely used in aerospace and medical industries.

Ti-6Al-2Sn-4Zr-2Mo: It offers high temperature and creep resistance, making it suitable for high-stress applications.

Steel & Hard Tool Steel

Steel and hard tool steel are recognized for their toughness and wear resistance, making them ideal for high-stress applications like cutting tools, molds, and heavy-duty machinery components.

D2: It is recognized for its high wear resistance and toughness.

H13: It offers high thermal stability and excellent resistance to thermal fatigue.

M2: It is a high-speed steel known for its exceptional toughness and hardness.

A2: It is an air-hardening steel characterized by good machinability and toughness.

Aluminum Alloys

Aluminum is lightweight and highly machinable, providing excellent corrosion resistance and electrical conductivity. It is commonly used in aerospace, automotive, and electronic applications.

6061: It is a versatile alloy known for its good mechanical properties and corrosion resistance.

7075: It is a high-strength alloy commonly used in aerospace applications, though it has lower corrosion resistance compared to 6061.

Carbides

Tungsten Carbide: It is extremely hard and wear-resistant, making it ideal for cutting tools and wear parts.

Cemented Carbide: It is a composite material known for its high hardness and toughness, making it ideal for machining applications.

Alloy Steels

Inconel: It is a nickel-chromium-based superalloy that offers excellent strength at high temperatures and outstanding oxidation resistance.

Hastelloy: It is a nickel-based alloy recognized for its exceptional corrosion resistance in harsh environments.

Copper Alloys

Brass: It offers good machinability along with excellent thermal and electrical conductivity.

Bronze: It is strong and highly resistant to wear and corrosion.

Copper-Nickel Alloys: It provides excellent corrosion resistance, particularly in marine environments.

Nickel Alloys

Inconel: It retains its strength and oxidation resistance even at elevated temperatures.

Monel: It is a nickel-copper alloy known for its excellent corrosion resistance and high strength.

Superalloys

Rene: It offers high-temperature strength and creep resistance, making it suitable for use in turbine engines.

Waspaloy: It exhibits excellent high-temperature strength along with corrosion and oxidation resistance.

Graphite

This material boasts high thermal and electrical conductivity, is easily machined, and is commonly used for EDM electrodes.

Ready to get started on your Wire EDM quote?

Start Your QuoteWire EDM Part Size Standards

We can accommodate a wide range of part sizes with wire EDM machining, from intricate micro components to larger, complex assemblies, ensuring precise compliance with dimensional standards.

| Small Parts (mm) | Medium Parts (mm) | Large Parts (mm) | |

| Maximum Length | 50 | 100 | 500 |

| Maximum Width | 30 | 70 | 300 |

| Maximum Height | 10 | 40 | 150 |

| Minimum Thickness | 0.5 | 1 | 5 |

| Tolerance | ±0.005 | ±0.01 | ±0.03 |

Applications of Wire EDM Parts

Wire EDM machining provides adaptability and precision, fostering innovation and quality across various industries.

Advantages of Wire EDM Machining

Wire EDM provides a range of significant benefits for precision machining:

FAQs

What are types of EDM machining?

There are three main types of EDM process.

Wire EDM: This technique uses a thin wire as an electrode to cut intricate shapes and contours in conductive materials with high precision. It’s perfect for creating complex parts with tight tolerances and is commonly utilized in industries like aerospace, medical, and electronics.

Sinker EDM (Ram EDM): This technique employs a custom-shaped electrode that is inserted into the workpiece to create detailed cavities and shapes. It is extensively used in mold-making, die production, and the manufacturing of components with intricate geometries.

Hole-Drilling EDM: This method specializes in drilling small, precise holes in hard materials. It is especially beneficial for creating cooling holes in turbine blades and serves as a preliminary process for wire EDM.

Can Wire EDM machine hard materials?

Yes, Wire EDM is highly effective for machining hard materials. This technique employs a thin wire electrode to erode material via electrical discharges, making it suitable for cutting tough, conductive materials like hardened tool steels, titanium, tungsten carbide, and superalloys. Unlike traditional machining methods, Wire EDM does not rely on mechanical force, which helps avoid issues such as tool wear and material distortion. This capability makes it ideal for creating intricate shapes and achieving tight tolerances in hard materials, essential in industries like aerospace, medical device manufacturing, and tool and die. Wire EDM delivers precision and high-quality finishes, even in the most challenging materials.

How accurate is wire EDM?

Wire EDM (Electrical Discharge Machining) delivers outstanding precision, achieving tolerances as tight as ±0.0001 inches (±2.5 microns). This high accuracy is enabled by the thin wire electrode and sophisticated computer controls that direct the machining process. Wire EDM can create intricate and complex shapes with consistent precision, making it ideal for applications in aerospace, medical devices, and high-precision manufacturing. Moreover, the process produces smooth surface finishes, often negating the need for further finishing work. This level of precision ensures that parts comply with the most stringent specifications and quality standards.

What shapes can Wire EDM create?

Wire EDM machining can create a wide variety of intricate shapes with exceptional precision. It excels at producing sharp internal corners, complex contours, and detailed patterns that are difficult to achieve with conventional machining. Wire EDM is capable of handling both 2D and 3D geometries, making it ideal for cutting thin walls, small holes, and narrow slots with high accuracy. This capability is crucial for applications that demand complex and precise shapes, such as aerospace components, medical devices, and detailed molds and dies. The versatility of Wire EDM ensures it can meet diverse and exacting design requirements.

Can Wire EDM cut very thick materials?

Yes, Wire EDM can efficiently cut very thick materials with precision. It is capable of handling materials up to 12 inches (300 mm) thick, depending on the machine and setup. The process employs a thin wire electrode to erode the material, enabling it to cut through dense and hard substances without distortion. This makes it ideal for applications that require precise cuts in thick materials, such as large molds, heavy-duty machine components, and aerospace parts. The precision and versatility of Wire EDM ensure consistent and accurate results, even with very thick materials.

What are the main limitations of Wire EDM?

Although Wire EDM is a highly precise and versatile machining process, it does have some limitations:

Material Restrictions: It is limited to cutting electrically conductive materials, which excludes non-metallic materials such as plastics, ceramics, and composites from being machined using this process.

Cutting Speed: The cutting speed of Wire EDM is typically slower than that of some traditional machining methods, especially when working with very thick materials. This can lead to longer production times for certain applications.

Operating Costs: The Wire EDM process necessitates a continuous supply of wire and dielectric fluid, contributing to higher operational expenses. Moreover, the cost of the wire can be considerable, particularly for long or intricate jobs.

Complex Setup: The setup and programming of Wire EDM machines can be intricate and time-consuming. Skilled operators are essential for optimizing the process and ensuring precision, which can increase labor costs.

Surface Finish: Although Wire EDM can produce excellent surface finishes, obtaining the highest quality may necessitate additional passes and slower cutting speeds, which can further extend machining time.

Sheet Metal Fabrication Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Newsletter

Suspendisse a neque diam. Donec lacinia quam vitae tristique scelerisque. Nullam at tincidunt felis.