OEM & Custom

Die Casting Service

Supplier in China

Get custom die cast metal parts delivered quickly. Request a quote today to begin. We are certified to ISO 9001:2015 and ISO 14001:2015 standards.

Why Choose US for Custom Die Casting Services

What is Die Casting?

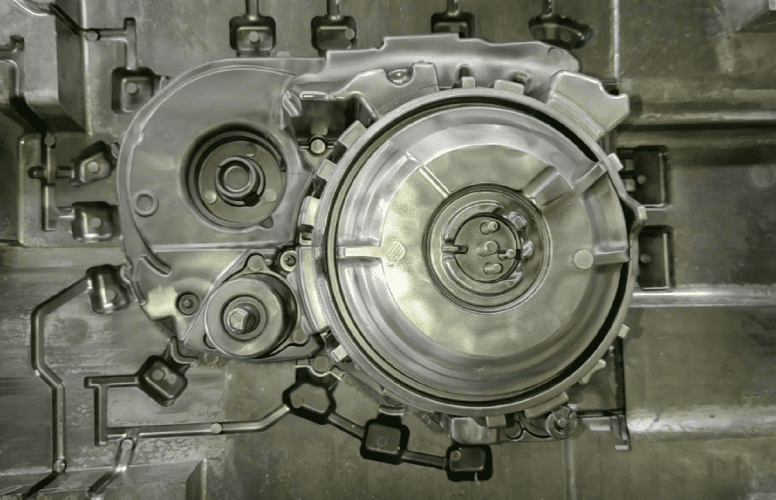

Die casting is a highly efficient manufacturing process for producing detailed, high-volume metal parts. It uses specialized molds called dies, designed to create multiple parts simultaneously, ensuring consistency and speed. Commonly applied to metals like aluminum and zinc, the process involves melting the metal and injecting it under high pressure into the dies.

The rapid cooling solidifies the metal, capturing intricate designs and minimizing the need for extensive secondary work. However, some projects may still require post-machining for tighter tolerances.

Our expert team carefully evaluates each die casting project to tailor methods to your needs, focusing on optimizing production flow and ensuring parts meet high standards of durability and appearance. By leveraging advanced techniques and precision machines, we deliver superior functional and aesthetic results, enhancing your product’s overall value.

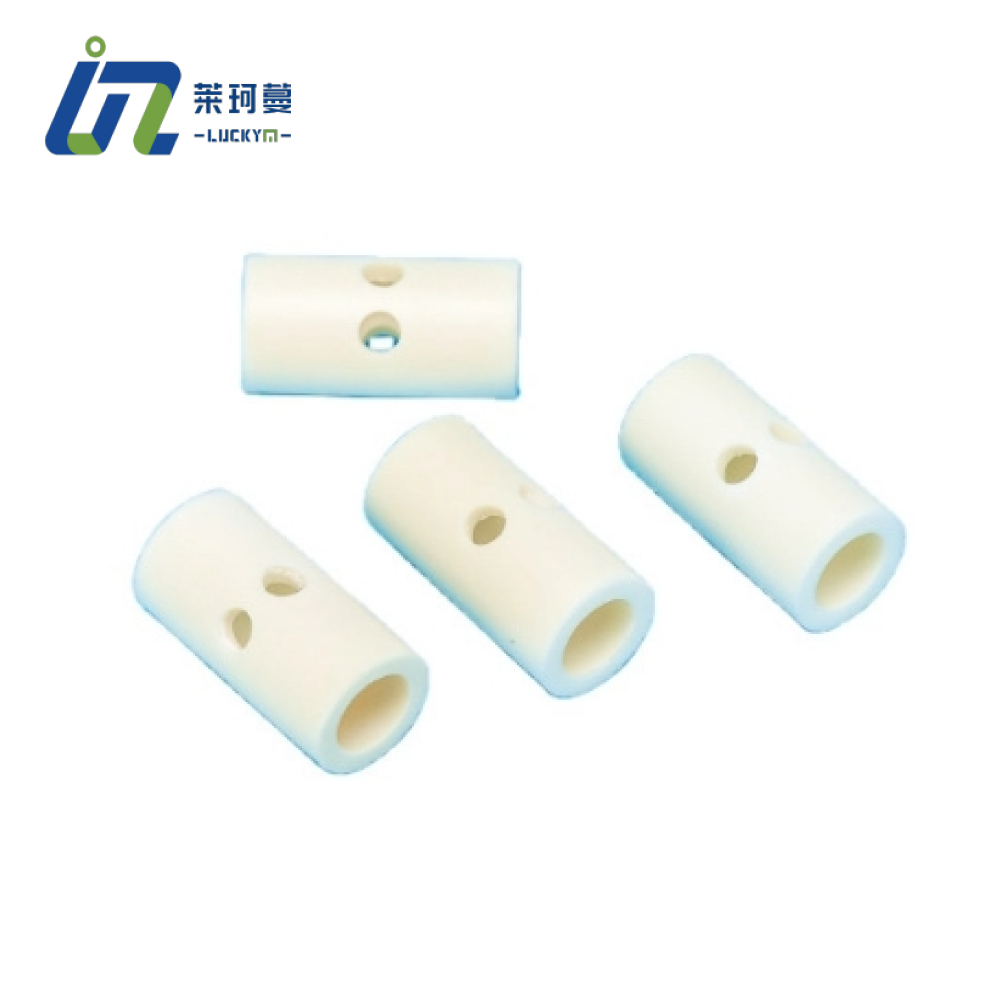

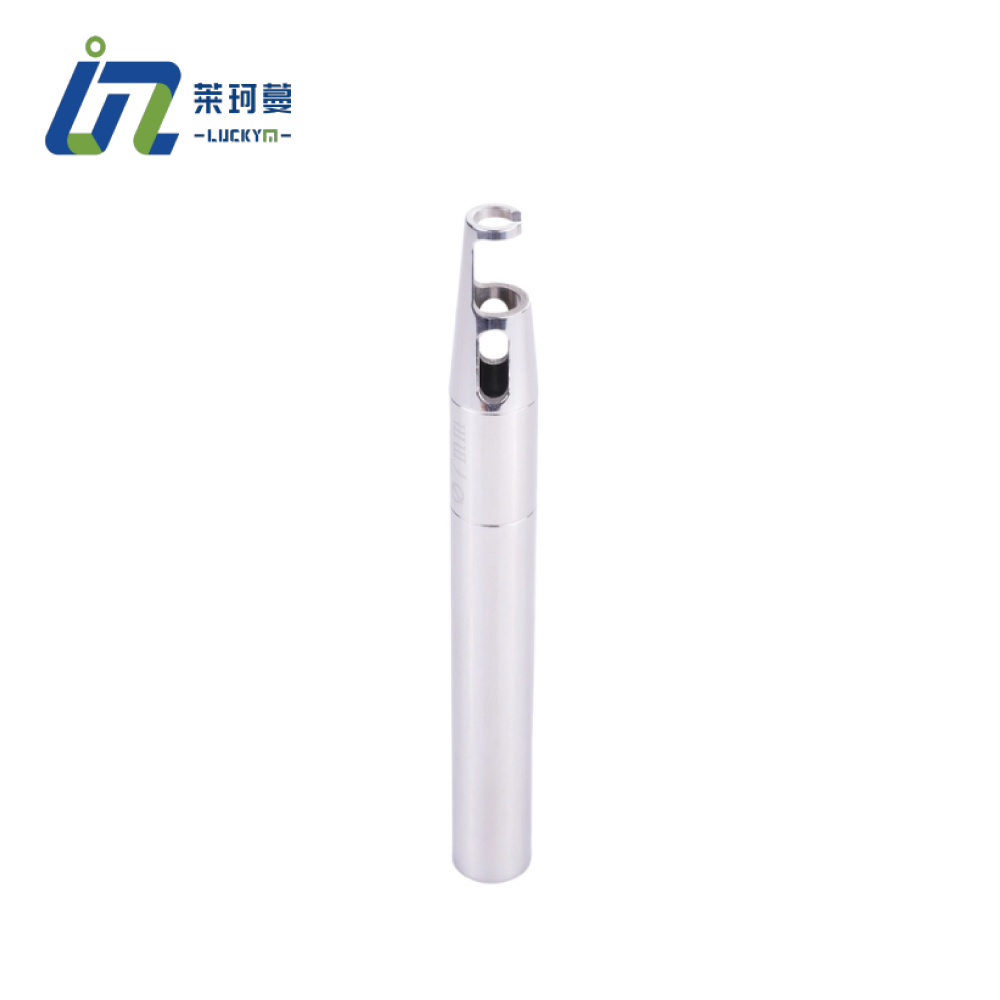

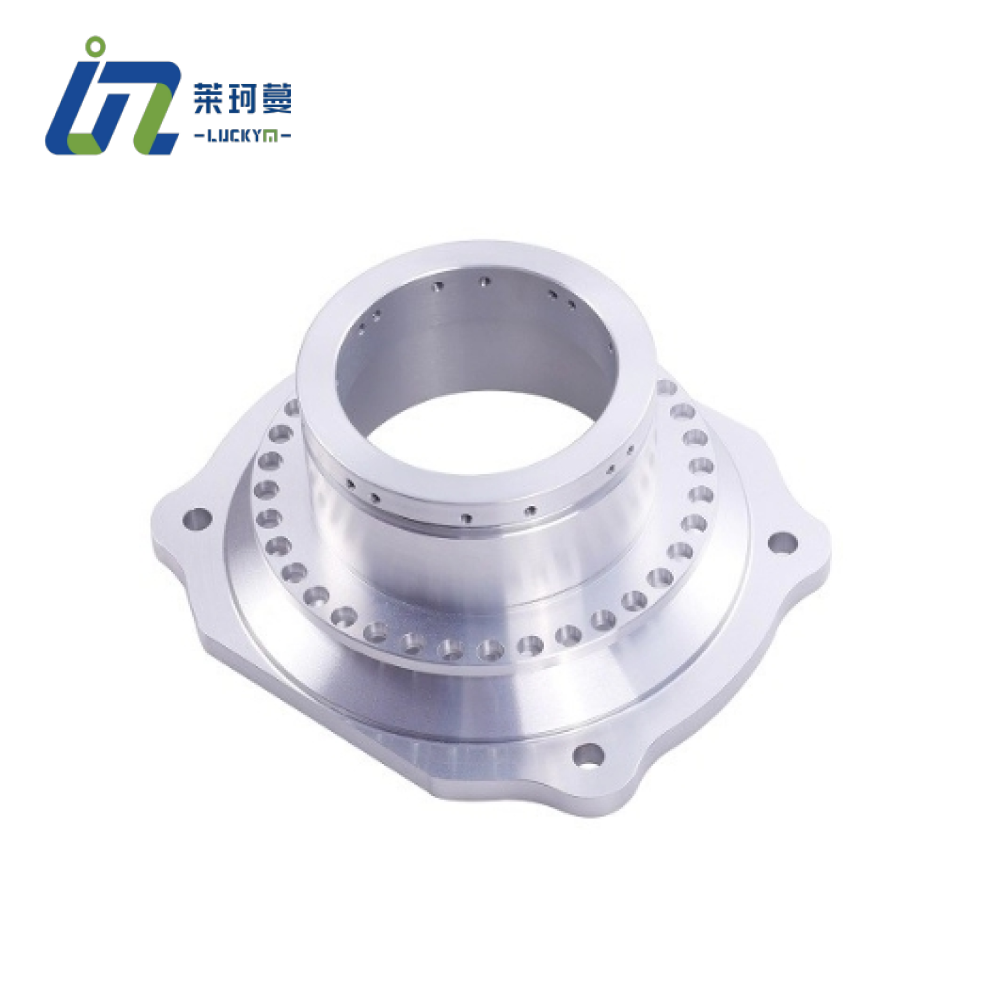

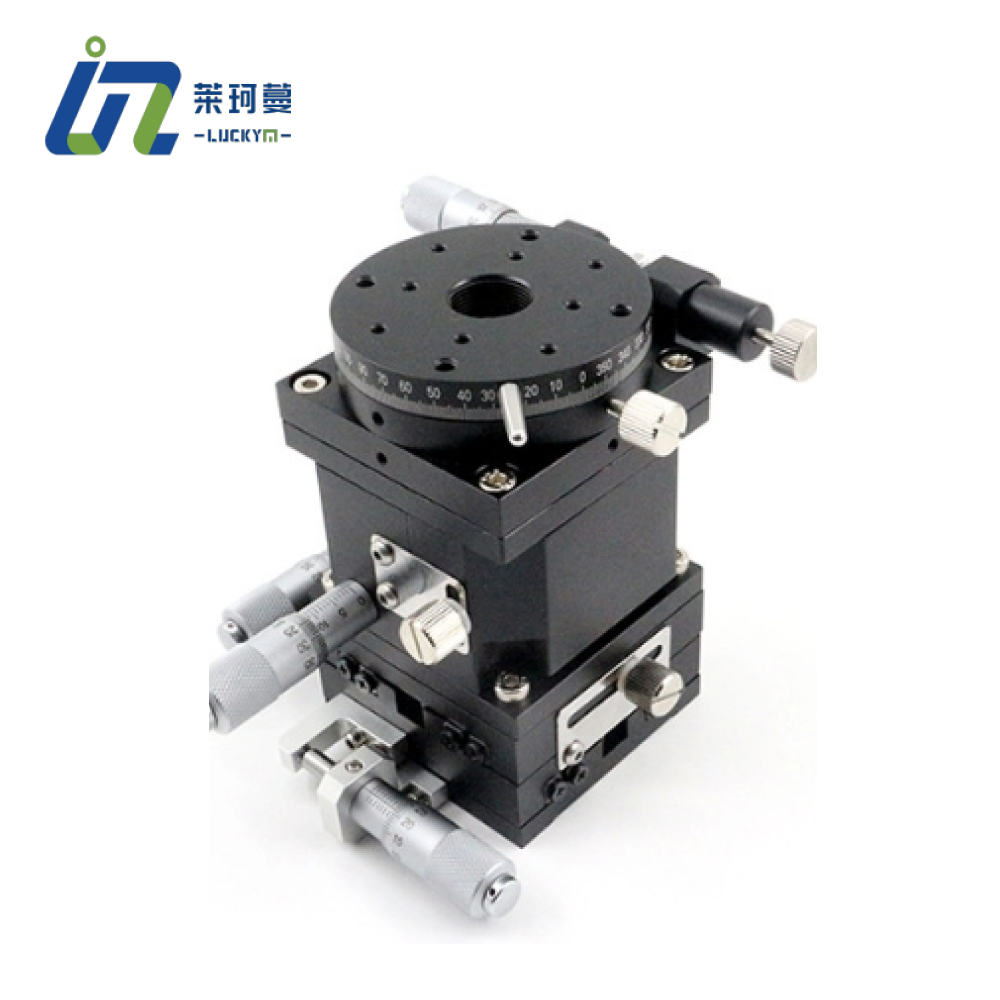

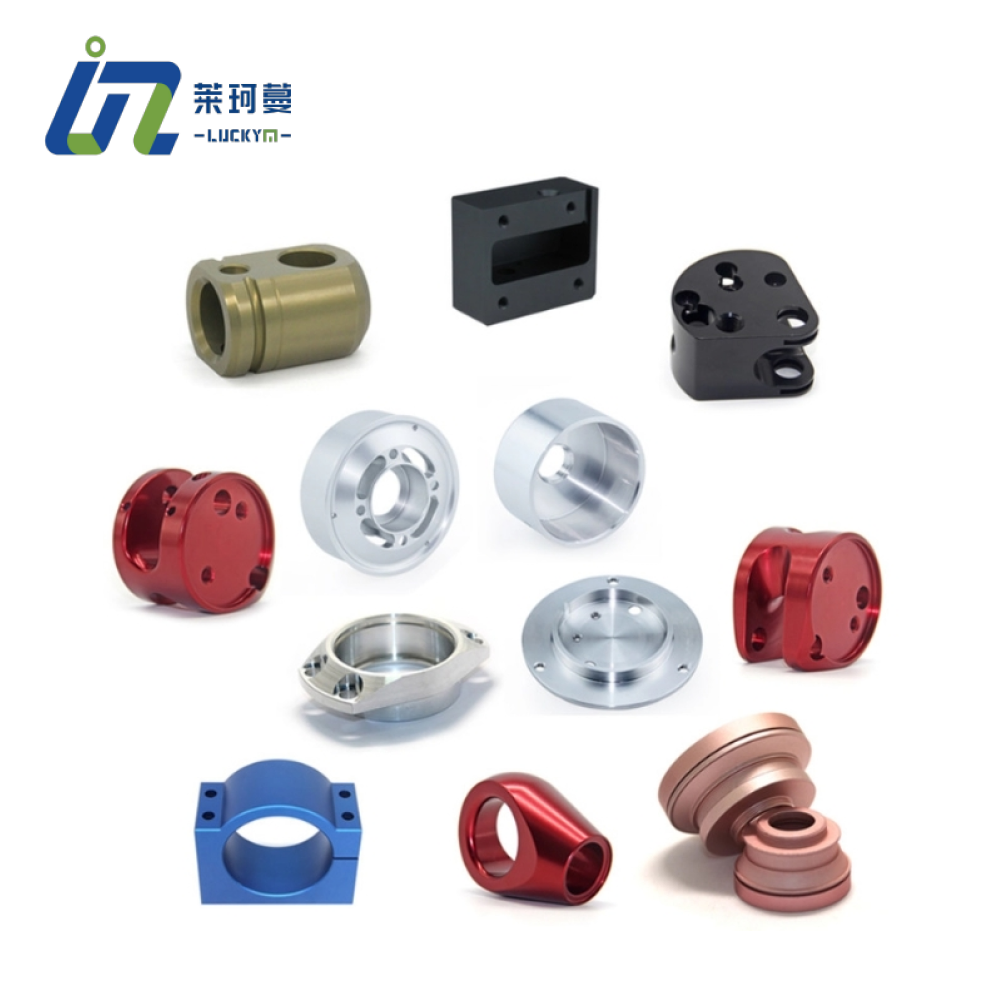

Gallery of Die Casting parts

Die Casting Materials

Metal Materials for Die Cast Parts

When it comes to die casting, there are various metal materials to choose from based on your product’s intended use. Our main materials include aluminum, zinc, magnesium, and copper, each selected for their distinct properties and advantages in die casting. If you have a specific material in mind, feel free to reach out to us!

- Aluminum ADC12、ADC6、A360、A380

- Zinc Zamak 3, Zamak 5, Zamak 2, ZA8

- Magnesium AZ91D, AM60B

- Copper ZQA19-2, ZQA19-4, ZQA19-7, ZQA19-10

Available Die Casting Surface Finishing

Standard (As-Cast)

This finish offers a basic, functional appearance for die-cast products, featuring relatively smooth surfaces with minor tool marks, making it suitable for non-cosmetic applications. Zinc and aluminum-zinc parts can be left as-cast while maintaining reasonable corrosion resistance. However, aluminum parts require coating to achieve similar protection. Cast components are usually detached from the casting sprue, resulting in rough marks at the gate locations, and most castings will also show visible marks from the ejector pins. The surface finish for as-cast zinc alloys typically ranges from 16 to 64 microinches Ra.

Polishing

This process improves the surface smoothness and shine of metal casts, minimizing roughness to create a high-gloss finish that is visually attractive.

Sand Blasting

This technique provides a consistent, matte finish by blasting the surface with fine particles, effectively removing small imperfections and preparing it for additional treatments.

Anodized (Type II Or Type III)

This process enhances the corrosion resistance and wear characteristics of aluminum cast parts while also allowing for coloration, improving both durability and visual appeal. Typically, aluminum undergoes anodizing, with Type II anodizing producing a corrosion-resistant oxide finish. While suppliers can anodize parts in various colors, the surface of a die-cast part does not support a cosmetic finish through anodizing. Type III anodizing offers a thicker finish, providing additional wear resistance alongside the corrosion protection of Type II. It’s important to note that anodized coatings are not electrically conductive.

Powder Coating

This process produces a thick, uniform coating that is more durable than traditional paint, making it ideal for adding vibrant colors and providing enhanced protection against corrosion and chipping. All die-cast parts can undergo powder coating, where powdered paint is electrostatically applied to the surface and then baked in an oven. This results in a strong, wear- and corrosion-resistant layer that outperforms standard wet painting methods. A wide range of colors is available to achieve the desired aesthetic.

Wet Painting

All die-cast parts can be wet painted using a diverse range of paint formulations and colors.

Plating

Die-cast parts can be plated with various materials, including electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver, and gold.

Chemical Film

Suppliers can apply a chromate conversion coating to safeguard aluminum against corrosion and enhance the adhesion of paints and primers. These chemical film conversion coatings are also electrically conductive.

Media Tumbled

Die-cast materials undergo vibratory media tumbling to eliminate sharp edges and achieve smooth surfaces.

Custom

Don’t see the Surface Finishing you require? Submit a Request for Quotation (RFQ), and our engineering team will explore suitable finishing processes for you.

Ready to get started on your Die Casting quote?

Start Your QuoteTypes of Die Casting Processes

We offer comprehensive die casting services using both Hot Chamber and Cold Chamber methods to meet various material needs and project specifications. Each method can produce parts with complex geometries, tight tolerances, and strong mechanical properties.

Applications of Die Casting

Die casting is a versatile manufacturing process valued for its precision and reliability across multiple industries. Here are some key applications:

- Automotive: Die casting is used for manufacturing durable components like engine blocks, gearboxes, and pistons with tight tolerances.

- Consumer Electronics: Ideal for producing robust and intricate parts in gadgets such as smartphones, laptops, and cameras.

- Lighting: Enables the creation of complex shapes for light fixtures and components, ensuring precision and quality.

- Medical Devices: Produces high-precision instruments and equipment parts, essential for reliability and sterility in healthcare.

- Industrial Machinery: Supplies parts for heavy machinery that demand high strength and resistance to challenging environments.

Advantages of Die Casting

Die casting provides several key advantages that make it a favored method for producing metal parts across diverse industries:

- High Precision and Consistency: Delivers tight tolerances and complex geometries reliably, making it perfect for the mass production of high-quality parts.

- Speed: Rapid production cycles are achieved through high-speed filling and quick cooling of molten metal, allowing for the swift manufacture of large quantities of parts.

- Strength and Weight: Creates durable yet lightweight parts due to the dense, fine-grained metal structure formed under high pressure.

- Minimal Waste: Ensures efficient material usage with minimal scrap, reducing waste and often lowering the need for additional machining.

- Complex Geometry: Die casting can effectively produce custom parts with thin walls and intricate shapes that are both durable and dimensionally stable.

Disadvantages of Die Casting

While die casting is advantageous for numerous applications, it does have certain limitations:

- High Initial Costs: The setup for die casting can be costly due to the expense of dies and machinery, making it less economical for small production runs.

- Limited to Certain Metals: Mainly effective for metals with lower melting points; casting high-melting metals can be difficult and less efficient.

- Porosity: The quick cooling of molten metal can cause air entrapment, leading to porous parts that may compromise structural integrity.

- Size Restrictions: Most effective for smaller components, as larger parts can pose challenges in achieving dimensional accuracy and uniformity.

- Post-Processing: Although minimal, certain die cast parts may require additional machining or finishing to achieve specific tolerances or surface finishes.

FAQs

What is the Die Casting Process?

Die casting is a metal casting technique that involves forcing molten metal into a mold cavity under high pressure. The mold, known as a “die,” is made from two hardened tool steel components that are machined to shape, functioning similarly to an injection mold. Here’s how the process works:

1. Mold Preparation: The die is prepared and lubricated to ensure easy removal of the casting and to help control temperature.

2. Molten Metal Injection: Molten metal is injected into the die at high pressures, typically between 10 and 175 megapascals (1,500 to 25,000 psi). This pressure is maintained until the metal solidifies.

3. Cooling and Solidification: The molten metal cools rapidly within the mold, solidifying into the desired shape.

4. Ejection: After solidification, the die halves are opened, and the cast part is ejected.

5. Trimming: Any excess material from the casting, such as gates, runners, and flash, is trimmed away.

Die Casting Design Considerations?

When designing parts for die casting, several key factors must be considered to ensure optimal performance and manufacturability:

1. Wall Thickness: Maintain uniform wall thickness to promote even cooling and solidification, reducing the risk of defects like warping or internal stresses. While thinner walls allow for faster cooling and material savings, their feasibility depends on the metal used and the complexity of the part.

2. Draft Angles: Draft angles should be considered when designing so that the casting can be easily ejected from the mold. Typically, a draft angle of at least 1 to 2 degrees is required, depending on the depth of the part.

3. Fillets and Radii: Fillets and fillet radii are used to eliminate sharp corners and edges that can cause stress concentrations and crack initiation points. This adjustment also enhances the flow of molten metal within the mold.

4. Gating System: Design an efficient gating system to ensure that the molten metal flows smoothly into the mold, minimizing turbulence and air entrapment. The location of the gate affects material distribution and part quality.

5. Venting: Proper venting must be planned to remove air and gases from the mold cavity during metal injection, preventing issues like porosity and incomplete filling.

6. Simplifying Geometry: Simplify the geometry as much as possible to avoid undercuts and complex features that require intricate die mechanisms, which can increase tooling costs and complicate the casting process.

What is vibration in die casting?

In die casting, vibration refers to the mechanical vibrations that occur within the die casting machine and die.

Vacuum pressure casting: This process requires a vacuum to be created within the die cavity to minimize air entrapment and porosity. In this environment, vibrations can disrupt the vacuum, causing defects in the final product.

Low pressure casting: Metal is introduced into the die at low pressure, and the die is susceptible to vibrations, which can affect the steady flow of molten metal and affect the consistency and integrity of the casting.

Semi-solid die casting: Semi-solid metal is injected into the die. Vibrations can affect the thixotropy of the metal, which can affect the filling pattern and performance of the final part.

Squeeze die casting: This process applies additional pressure after the initial fill to increase the density and mechanical properties of the casting. Vibrations at this stage can cause uneven pressure application, resulting in inconsistent casting quality.

What is the manufacturing cycle for die casting tools?

The manufacturing cycle for die casting molds is typically 2 to 12 weeks. This cycle starts from the initial design stage (part concept development and specification formulation) and continues until the mold is completed. The complexity of the part design, the specific metal selected for casting, and the precision required for the final product can significantly affect the duration of the mold manufacturing process. In addition, once the mold is machined, it needs to be rigorously tested to ensure that it meets quality standards. Any necessary adjustments or modifications to the mold to correct defects or improve functionality will increase the total lead time. Effective communication between the manufacturing team and the customer is essential to streamline the process and meet production deadlines.

What are the tolerances for die casting?

Die casting is a precision manufacturing process that is capable of very tight tolerances, making it ideal for producing complex, high-volume parts. In general, die casting tolerances depend on part size, the metal used, and the specific casting process. Tolerances for standard sizes range from ±0.1 mm (less than 25 mm) to ±0.5 mm (up to 250 mm). More precise tolerances as low as ±0.02 mm can be achieved through additional post-machining processes.

The material also plays a crucial role in defining tolerances. Metals such as aluminum and zinc alloys have different shrinkage and mechanical properties, which can affect the final dimensional accuracy. Advanced die casting techniques such as vacuum casting or squeeze casting can further enhance tolerance control by reducing porosity and improving the integrity of the metal.

Can you post-process die castings?

Yes, post-processing of die castings is not only possible, but often necessary to achieve precision and surface finishes that are not achievable with die casting alone. Post-processing allows for tighter tolerances and smoother surfaces, which are essential for high performance and aesthetics. Common post-processing processes include drilling, milling, and CNC machining, which can refine features on die castings to exact specifications.

In addition, post-processing can correct any minor defects that occurred during the casting process, such as porosity or surface imperfections. It can also add complex features and fine details that are not achievable with casting alone. By combining die casting with post-processing, manufacturers can leverage the speed and cost-effectiveness of die casting to achieve the blank shape while achieving the accuracy of CNC machining to achieve critical dimensions and surface finish.

Die Casting Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Newsletter

Suspendisse a neque diam. Donec lacinia quam vitae tristique scelerisque. Nullam at tincidunt felis.