OEM & Custom

CNC Machining Service

Supplier in China

Obtain instant quotes for custom metal and plastic machined parts through our precision CNC Machining Service. Transition swiftly from prototype to mass production using a variety of world-class CNC machines.

First-class CNC machining services

As a professional CNC machining factory, our company is committed to serving the global market. Our factory has passed ISO9001:2015 certification and ISO14001: 2015 certification, with nearly 100 CNC machining centers to meet the growing needs of global customers and the long-term development of our company. Utilizing the most advanced CNC machining technology, our experienced machinists, engineers and professional quality inspection team work together to ensure that your products are completed correctly and shipped on time.

Why Choose US for Custom CNC Machining Services

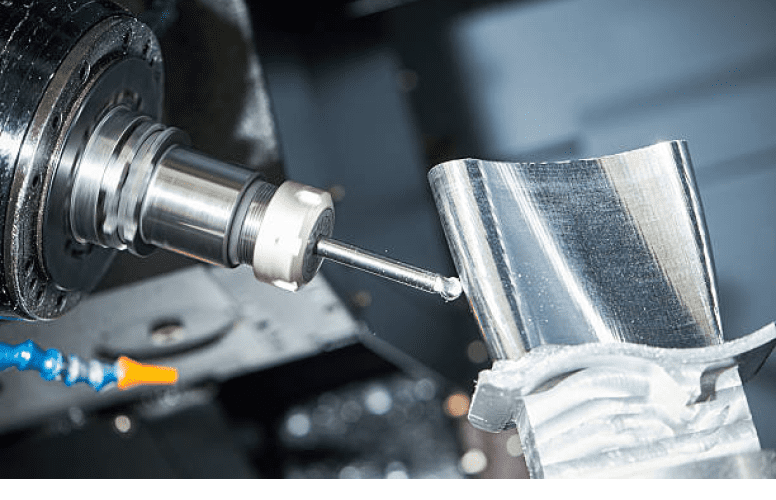

CNC Milling Service

CNC milling is one of the most common processing methods, mainly used to process various sizes of special-shaped parts. As a typical “subtractive” processing method, the raw materials for milling need to be strictly selected and measured to ensure the quality of the workpiece while generating the least waste, thereby reducing production costs. Our company is equipped with first-class CNC machining centers and clamping equipment to realize your design quickly and accurately. The following is our CNC milling parameter table.

Maximum Dimensions

Maximum depth that can be milled is 2 in. (50.8mm) from either side of part.

| Material | IN. | MM | |

| 3-axis | Plastic | 51.18*27.56*27.56 | 1300*700*700 |

| Metal | 51.18*27.56*27.56 | 1300*700*700 | |

| 4-axis | Plastic | 17.71*15.75*15.75 | 450*400*300 |

| Metal | 17.71*15.75*15.75 | 450*400*300 | |

| 5-axis | Plastic | 31.50*37.40*40.16 | 800*950*1020 |

| Metal | 31.50*37.40*40.16 | 800*950*1020 |

Minimum Dimensions

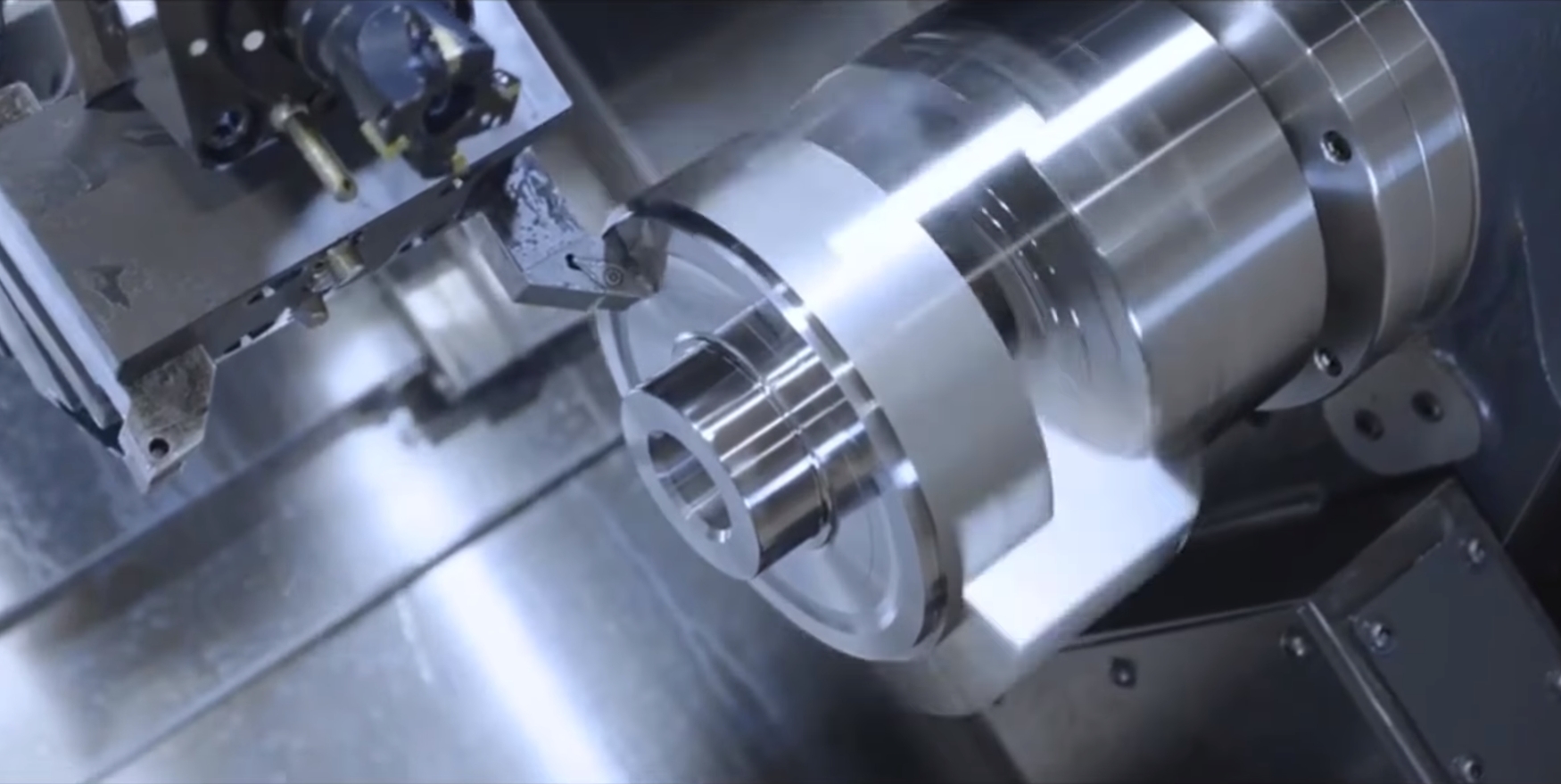

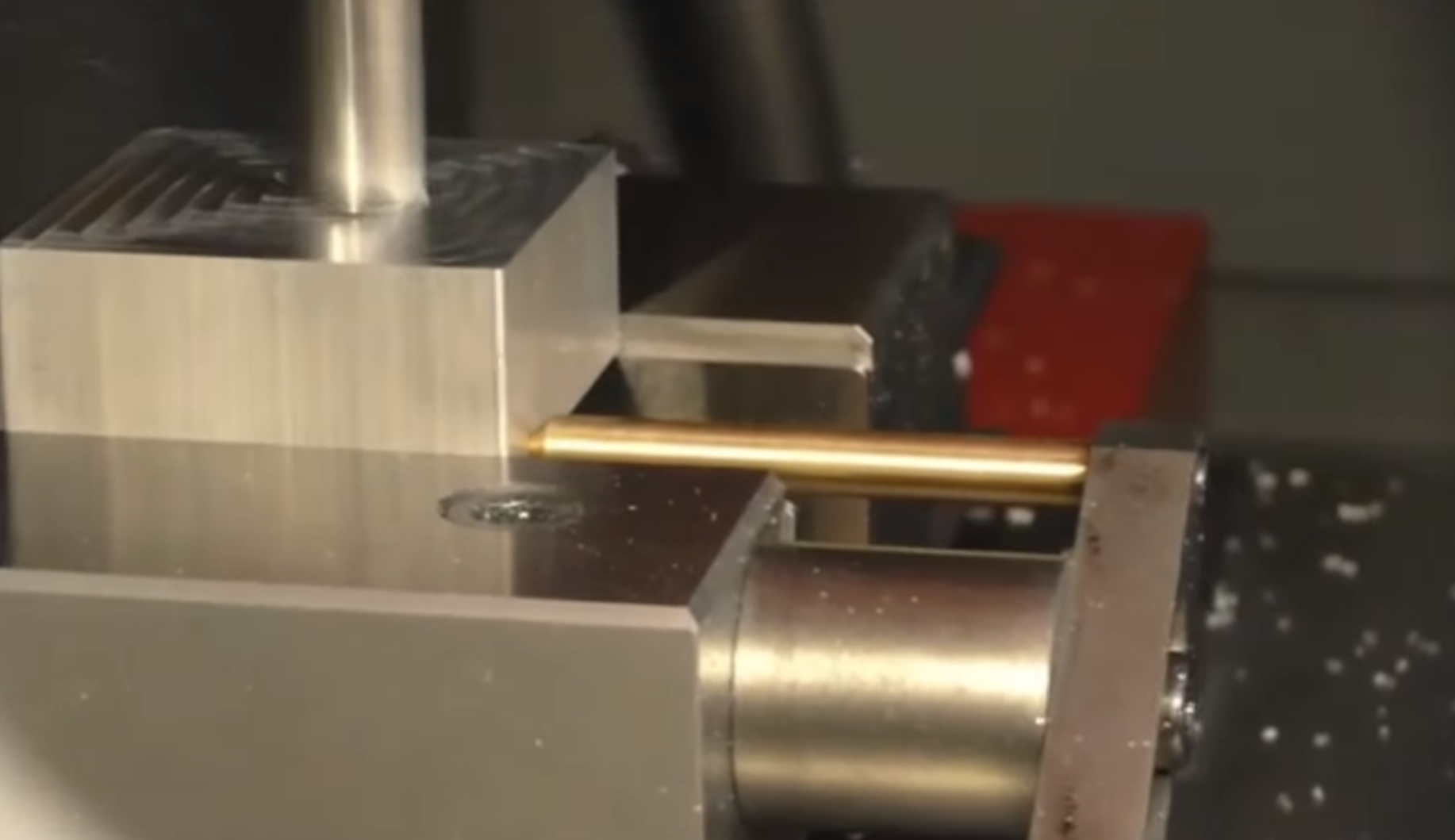

CNC Turning Service

CNC turning is also the most common “subtractive” processing method. CNC lathes use special clamping devices to fix materials, drive materials to rotate at high speed, and use special tools in the tool magazine to quickly cut the materials to obtain the desired product shape. Turning has the advantages of high precision, high finish, and high efficiency. It is the only choice for rapid proofing and batch processing.

| Material | IN. | MM | |

| Maximum Dimensions | Diameter | 19.69 | 500 |

| Length | 23.62 | 600 | |

| Tolerances | ±0.0002 | ±0.005 | |

| Minimum Dimensions | Length | 0.02 | 0.5 |

| Wall Thickness | 0.02 | 0.5 | |

| Diameter | 0.118 | 3 |

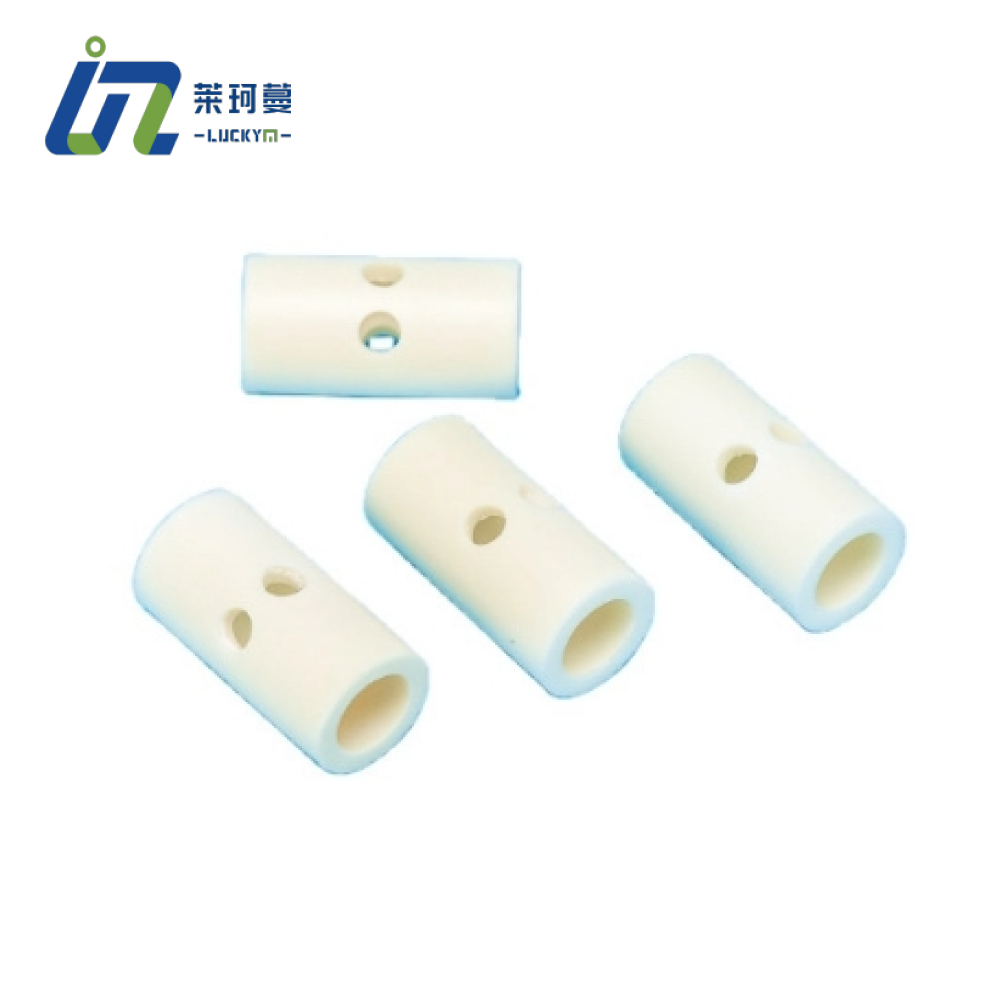

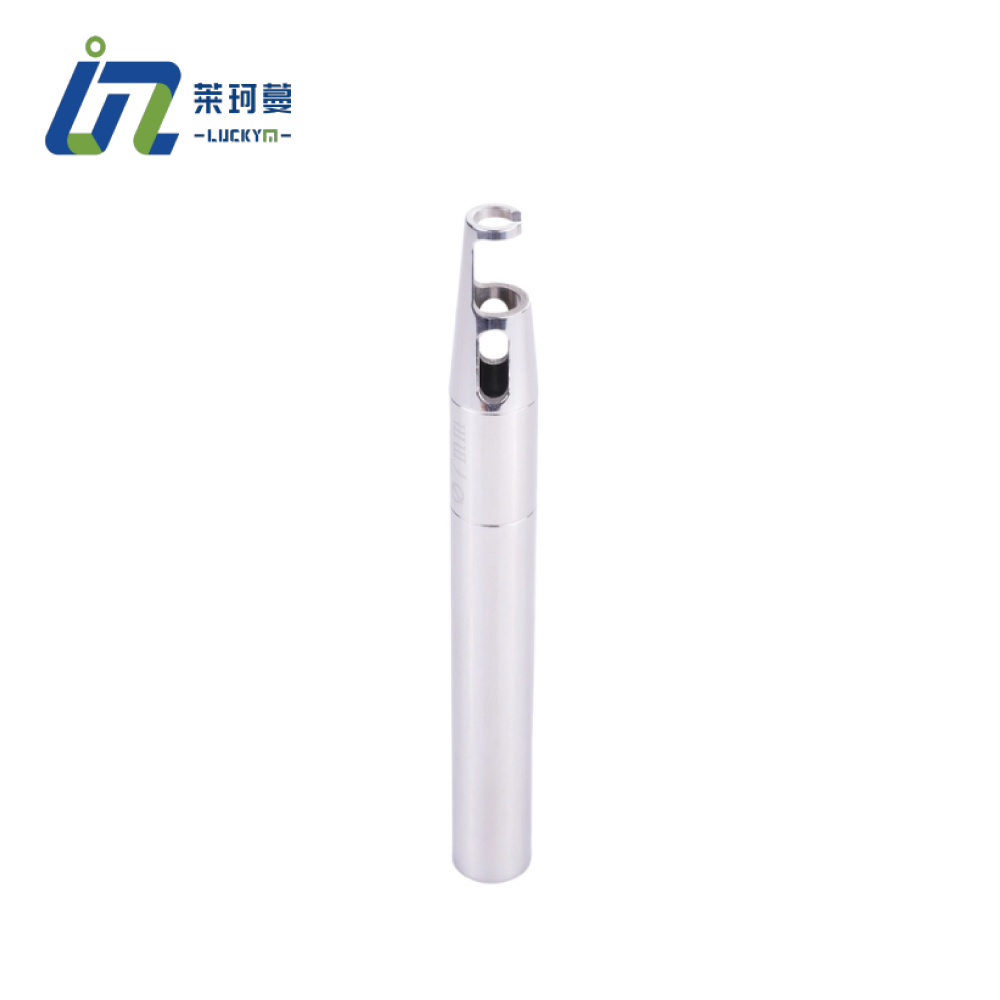

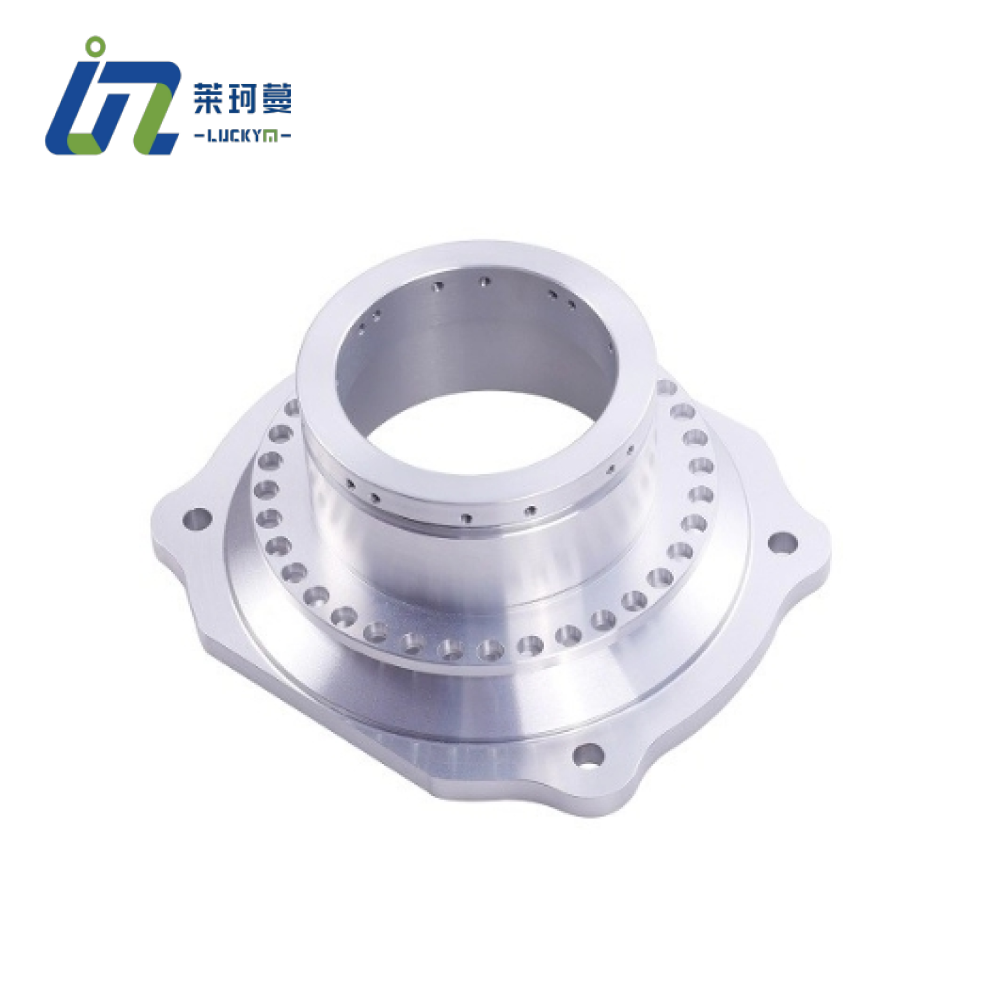

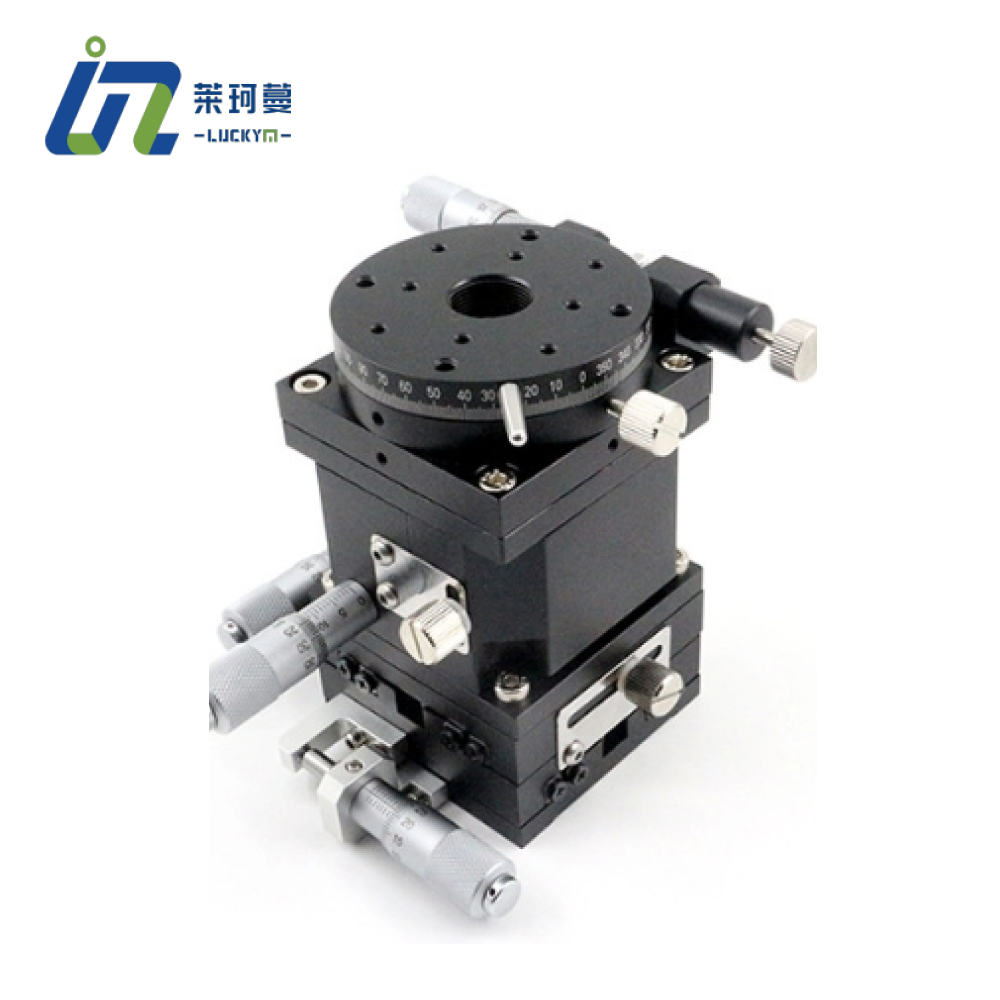

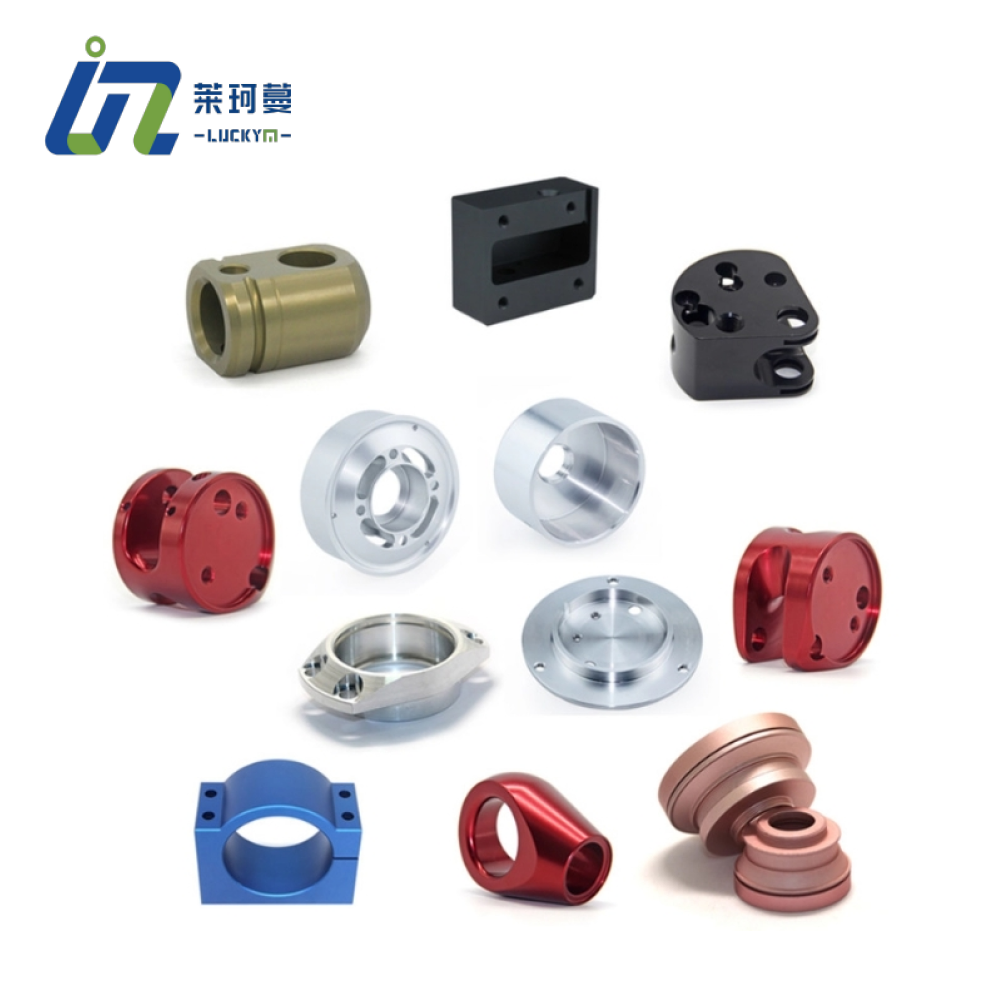

Gallery of CNC Machining parts

CNC Machining Materials

Metal CNC Machining Materials

Aluminium Alloys

The most widely used nonferrous metal in industry, as a soft, light and durable metal material, is often used in aerospace, automobile, machinery manufacturing, shipbuilding and industrial development. The customized aluminum products processed by our company have various appearance and color options, and a full range of surface treatments to meet the needs of different industries.

Color: Subtypes: Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing Copper

It has good electrical and thermal conductivity, excellent plasticity, and is easy to process by hot and cold pressing. It is mainly used to make electrical equipment such as generators, busbars, cables, switchgear, transformers, and heat exchangers, pipelines, flat collectors for solar heating devices, and other heat-conducting equipment.

Color: Subtypes: Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper Available Finish: As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickel, Chrome plating, Brushed finish Bronze

Bronze, an alloy of copper and tin, is renowned for its durability and corrosion resistance. Due to its high strength and capability to endure harsh environments, bronze is commonly used in marine applications, sculptures, and bearings.

Color: Subtypes: Tin Bronze Available Finish: As machined, Polishing, Sand blasting, Tumbling, Electropolish, Alodine, Heat treatment, Black oxidize, Electroless nickle, Chrome plating, Powder coating, Brushed finish Brass

Brass is an alloy of copper and zinc with high strength, excellent machinability and wear resistance. The surface of brass will gradually oxidize and turn black in the air, but an oxide film will form to protect the inside. It is often used to manufacture precision instruments, ship parts, automotive parts, medical accessories, electrical accessories, industrial products and other precision parts.

Color: Subtypes: Copper 260, Copper 360

Available Finish: Steel

Steel is a strong, durable and versatile material that is extensively used in construction and manufacturing. Its high tensile strength makes it ideal for structural components, while various subtypes enhance its performance, making it suitable for special applications such as tools and machinery.

Color: Subtypes: Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC Available Finish: As machined, Electroplating, Passivation, Powder coating Stainless Steel

Stainless steel has the characteristics of corrosion resistance, high temperature resistance, and ultra-low temperature resistance. It has a wide range of applications and can be used to manufacture medical devices, automotive parts, industrial products, etc.

Color: Subtypes: Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 Avaiblae Finish: As machined, Electroplating, Passivation, Powder coating Magnesium

It has the characteristics of high strength, high rigidity, low density and wear resistance. It is the lightest metal among practical metals, with high stability, high dimensional accuracy and can be processed with high precision. It is mainly used in aviation, aerospace, transportation, chemical industry, rocket and other industrial fields.

Color: Subtypes: Magnesium Alloy AZ31B, AZ91D Available Finish: As machined, Polishing, Sand Blasting, Tumbling, Alodine, Heat treatment, Anodizing, Teflon coating, Electroless nickel, Painting, Powder coating, Electrophoresis Titanium

Titanium (titanium alloy) is a structural metal with the characteristics of light weight, high strength, good corrosion resistance and high heat resistance. It is often used to process important parts in the automotive, aerospace, shipbuilding, medical and other industries.

Color: Subtypes: Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V Available Finish: As machined, Polishing, Sand Blasting, Tumbling, Electropolish, Alodine, Anodizing, Electroless nickel, Painting, Powder coating, Brushed finish

Plastic CNC Machining Materials

ABS

It is a thermoplastic polymer structural material with high strength, good toughness and easy processing. It is also a low-cost engineering plastic with good processing performance, strong mechanical properties and a wide range of applications. It is an excellent choice for producing parts.

Color: Subtypes: ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White Available Finish: As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating, Electrophoresis PC

Polycarbonate, referred to as PC engineering plastics, is an amorphous thermoplastic resin with excellent comprehensive performance. It has excellent electrical insulation, ductility, dimensional stability and chemical resistance. It is an engineering plastic with high strength and weather resistance.

Color: Subtypes: PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black Available Finish: As machined, Sand blasting, Tumbling, Painting, Brushed Finish PMMA (Acrylic)

PMMA(Polymethyl methacrylate), also known as acrylic, has the characteristics of good transparency, good chemical stability, good weather resistance, easy dyeing, easy processing, strong plasticity, and beautiful appearance. It is widely used in medical, industrial, automotive and other fields. However, its thin-walled parts are fragile during processing, so it is not recommended for processing fine or complex geometric parts.

Color: Subtypes: PMMA Black, PMMA Transparent, PMMA White Available Finish: As machined, Sand blasting, Tumbling, Painting POM

POM (polyoxymethylene) is a high-hardness, high-rigidity, wear-resistant engineering plastic with good surface hardness and density. It is suitable for products that play a skeleton role in gears, bearings, automotive parts, machine tools, and internal parts of instruments.

Color: Subtypes: Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White Available Finish: As machined, Sand blasting, Tumbling, Painting PA (Nylon)

Nylon (PA), also known as polyamide, is the most important engineering plastic, covering almost all application fields. It is widely used in chemical machinery, anti-corrosion equipment gears and parts blanks, transmission structural parts, home appliance parts, automotive parts, etc.

Color: Subtypes: PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black Available Finish: As machined, Sand blasting, Tumbling, Teflon coating, Painting, Powder coating PE

Polyethylene is lightweight and durable, offering excellent impact resistance. It is a preferred material for packaging, containers, and applications that require resistance to cracking under pressure.

Color: Subtypes: HDPE, UHMW-PE, LDPE Available Finish: As machined, Sand blasting, Tumbling, Painting, Powder coating PEEK

PEEK (poly-ether-ether-ketones) is a high-performance specialty engineering plastic that serves as a lightweight alternative to most soft metals. It boasts outstanding mechanical properties, self-lubrication, chemical resistance, and wear resistance. PEEK is commonly used in aerospace, automotive manufacturing, electrical and electronics, medical applications, and various other fields.

Color: Subtypes: PEEK Beige(Natural), PEEK Black Available Finish: As machined, Sand blasting, Tumbling, Painting, Powder coating PP

Polypropylene is currently one of the lightest types of plastic available, featuring high heat resistance, excellent mechanical properties, environmental protection, and non-toxicity. It is ideal for manufacturing general mechanical parts, corrosion-resistant components, and insulating parts.

Color: Subtypes: PP Black, PP White, PP+GF30 Black Available Finish: As machined, Sand blasting, Tumbling, Painting, Powder coating HDPE

HDPE is exceptionally strong and impact-resistant, boasting a high strength-to-density ratio. It is ideal for bottles, containers, and pipes that must endure outdoor wear and tear.

Color: Subtypes: HDPE Black, HDPE White Available Finish: As machined, Sand blasting, Tumbling, Painting, Powder coating, Teflon coating HIPS

HIPS is easy to machine and offers great impact resistance, making it an excellent choice for prototypes, models, and temporary displays that require a lightweight yet sturdy material.

Color: Subtypes: HIPS Board White Available Finish: As machined, Sand blasting, Tumbling, Painting, Powder coating, Brushed finish LDPE

LDPE is soft, flexible, and crack-resistant, making it ideal for plastic bags, tubing, and shrink wrap where heat sealing is crucial.

Color: Subtypes: LDPE White Available Finish: As machined, Painting, Powder coating, Teflon coating PBT

PBT is a rigid, heat-resistant material that also offers moisture resistance. It is commonly used in electrical parts, automotive components, and industrial connectors where high temperatures or wet conditions are a concern.

Color: Subtypes: PBT Black, PBT Milky White (Natural) Available Finish: As machined, Sand blasting, Tumbling, Painting, Powder coating PPA

PPA provides heat resistance and stiffness, making it ideal for automotive and electrical applications that require durability at high temperatures.

Color: Subtypes: PPA Beige Available Finish: As machined, Sand blasting, Tumbling, Painting, Teflon coating, Brushed finish PAI is renowned for its exceptional thermal and chemical stability. It’s a top choice in the aerospace and automotive sectors, used for high-performance parts that endure extreme conditions.

Color: Subtypes: PAI 4203, 4503, 4301, 4501 Available Finish: As machined, Sand blasting, Tumbling, Heat Treatment, Teflon Coating, Painting PET

PET is strong, moisture-resistant, and recyclable. It is commonly used in food containers, bottles, and textiles, and it withstands wear and tear over time.

Color: Subtypes: PET Black, PET White, PET+GF30 Black, PET+GF30 White Available Finish: As machined, Sand blasting, Tumbling, Teflon Coating, Painting PPS

PPS is heat- and chemical-resistant, making it an excellent choice for automotive, aerospace, and industrial parts that must endure harsh environments while maintaining structural integrity under stress.

Color: Subtypes: PPS Black, PPS White, PPS+GF30 Black Available Finish: As machined, Sand blasting, Tumbling, Teflon Coating, Painting PS

Polystyrene is lightweight and easy to mold, making it a popular choice for models, prototypes, and disposable packaging where shaping is more important than strength.

Color: Subtypes: PS Transparent Available Finish: As machined, Sand blasting, Painting PVC

PVC is durable, cost-effective, and resistant to chemicals. Commonly used in plumbing pipes, medical devices, and electrical cables, it offers excellent protection against corrosion and wear.

Color: Subtypes: PVC Grey Available Finish: As machined, Sand blasting, Painting, Teflon coating, Powder coating PTFE (Teflon)

Commonly known as “Plastic King”, this material boasts impressive properties, including resistance to both high and low temperatures, chemical corrosion, a low friction coefficient, self-lubrication, and non-stickiness. It is widely utilized across various industries, including aerospace, electronics, electrical, chemical, and machinery.

Color: Subtypes: Teflon (PTFE) Black, Teflon (PTFE) White Available Finish: As machined, Sand blasting, Powder coating, Brushed finish UPE

UPE is durable, featuring long polymer chains that make it perfect for abrasion-resistant applications, such as lining chutes and creating wear-resistant surfaces that experience heavy use.

Color: Subtypes: UPE Black, UPE White Available Finish: As machined, Sand blasting, Teflon coating, Painting Bakelite

Bakelite is heat-resistant, electrically non-conductive, and highly durable. It is commonly used in electrical insulators and vintage electronics, where safety and long-lasting performance are essential.

Color: Subtypes: Bakelite Black, Bakelite Orange Available Finish: As machined, Painting, Powder coating, Brushed finish FR-4

FR-4 is flame-resistant, robust, and an effective electrical insulator. It is mainly used in electronics for circuit boards and components that must endure heat and electrical stress.

Color: Subtypes: FR-4 Aqua Green, FR-4 Yellow

Available CNC Machining Surface Finishing

As Machined

A machined finish comes directly from the CNC machine, offering a cost-effective option that retains tool marks on the surface.

Anodizing

Anodizing not only provides beautiful appearance color, but also improves the hardness and durability of the workpiece. In some cases, it is more ideal than painting.

Sand Blasting

Sandblasting is the process of spraying fine sand onto the workpiece through high-pressure airflow, which removes burrs and stains on the surface of the workpiece while forming a unique texture. Sandblasting can be used as a final treatment or as a preparation for subsequent surface treatment to increase the bonding strength between the workpiece and the coating or plating layer.

Painting

Experienced spray painting masters can mix thousands of colors and provide matte, semi-gloss and full-gloss surface effects. Thanks to our strict quality control, all products can be sprayed with uniform thickness and no color difference.

Powder Coating

Utilize professional equipment to apply electrostatic powder to the workpiece surface, creating a uniform coating with various effects. Powder coating provides a thick, wear-resistant layer available in a wide range of colors and textures, making it suitable for diverse surfaces.

PVD

PVD is an environmentally friendly coating process with the characteristics of high hardness, wear resistance, corrosion resistance, high chemical stability and long life. The products treated by this process have very dazzling color effects and rich layers, which greatly improves the ornamental value of the products.

Electrophoresis

This process can make the inner layer, depression, weld and other parts of the workpiece obtain a uniform and smooth paint film, solving the problem that other treatment methods are difficult to coat workpieces with complex shapes, and the product has a long-lasting bright color and good corrosion resistance.

Electroplating

Electroplating applies a thin metal layer to components, enhancing wear resistance, corrosion resistance, and surface conductivity. This process encompasses various methods, including vacuum electroplating, UV electroplating, plastic electroplating, and metal electroplating. Its widespread technology is ideal for mass production and facilitates mechanization and automation.

Passivation

Passivation exhibits characteristics that change the color of the workpiece without increasing its thickness, thereby enhancing the precision of the product and improving the corrosion resistance of the metal. This process also maintains the metal surface’s original characteristics and increases its added value.

Laser Engraving

Laser engraving produces intricate, clear, and beautiful logos and patterns that resist wear and fading from touch, temperature changes, and other factors. This method can engrave complex designs and images on both metal and non-metal materials.

Silkscreen Printing

The silkscreen printing process can be freely matched with various inks and coatings to make the pattern colorful, bright, and three-dimensional, and can be applied to various materials and shapes.

Polishing

Polishing produces a high-gloss finish by minimizing surface roughness and enhancing the visual appeal of metals.

Brushed Finish

A brushed finish imparts a unidirectional satin texture, effectively minimizing the visibility of marks and scratches on the surface.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that enhances corrosion resistance and reduces light reflection.

Electropolish

Electropolish is a chemical process that polishes and brightens surfaces while enhancing corrosion resistance.

Alodine

Alodine coating offers corrosion protection and enhances paint adhesion, primarily applied to aluminum surfaces.

Heat Treatment

Heat treatment modifies the mechanical properties of metal to enhance its hardness, strength, or ductility.

Tumbled

This batch-based process uses vibrating media to smooth sharp edges and burrs on CNC parts. Tumbling can also eliminate machine marks on exterior surfaces. Parts larger than 8 inches may require manual inspection.

Titanium Anodize

A surface finish for titanium according to AMS-2488 Type 2 specification, also known as Tiodize, enhances fatigue strength and wear resistance. Titanium anodized parts are widely used in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes may appear dull.

PTFE Impregnated Hard Anodize

This hard coat anodizing process incorporates PTFE to produce a self-lubricating, dry contact surface while retaining the protective properties of a Type 3 hard coat. Suitable for aluminum alloys or titanium, this finish extends the service life of the product. It conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed) specification.

Chem Film (Chromate Conversion Coating)

This coating offers corrosion resistance and good conductivity. It can serve as a base for paint and may leave a yellow or gold surface. The thickness added is minimal, ranging from 0.00001 to 0.00004 inches. The chemical film conforms to MIL-DTL-5541, TYPE I/II standards.

Electroless Nickel Plating

This process provides a uniform nickel coating that protects against corrosion, oxidation, and wear on irregular surfaces. The finished part has a brighter appearance, with a thickness starting at 0.0001 inches. It conforms to MIL-C-26074 standards.

Silver Plating

Silver provides excellent solderability and electrical conductivity, though it is prone to tarnishing. It conforms to AMS QQ-S-365D standards, with a thickness ranging from 0.00002 to 0.0003 inches.

Gold Plating

Gold plating offers strong corrosion and tarnish resistance along with excellent solderability. The standard application specifications are MIL-G-45204 and ASTM B488, CLASS 00, 0, or 1. The thickness typically ranges from 0.00002 to 0.00005 inches.

Zinc Plating

This process delivers a uniform zinc coating that protects against corrosion, oxidation, and wear on irregular surfaces. It conforms to ASTM B633-15 standards.

Ready to get started on your CNC Machining quote?

Start Your QuoteProcess flow of CNC machining parts

1. Send drawings

We provide customized CNC machining services based on your design drawings. In order to protect the privacy of customers, we can sign NDA with you to ensure information security.

2. Material inspection

All materials are accompanied by certificates of conformity and are tested by professional equipment to ensure that the material quality meets expectations.

3. Programming

Our experienced team of engineers will program your design drawings with professional software to promptly find out whether the design is machinable and provide you with modification suggestions when necessary.

4. CNC machining

CNC machining is generally divided into roughing and finishing. Roughing will cut a large amount of raw materials to process the general outline of the product. The amount of cutting each time during finishing is very small to ensure that the error of each size of the product is within the allowable range.

5. Quality inspection

The processed products need to be fully inspected to ensure that the product dimensional tolerance is within the allowable range of the design drawings. The product will be carefully polished as needed after removing burrs. If you have special surface treatment requirements, we can provide you with anodizing, powder coating, painting, electroplating, PVD and other services

6. Packaging

All products will be packaged after QC is completed. The inner packaging uses anti-collision foam and fills the gaps to avoid damage to the product due to shaking and impact during transportation. The outer box uses 4-layer cardboard or wooden boxes as needed to provide secondary protection.

CNC Machining for Various Industries

Our CNC machining can meet the precise needs of various industries, such as Aerospace, Automotive, Automation, Medical Devices, Robotics, Consumer Products, etc.

FAQs

What is CNC machining?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses computerized controls and precise programming to direct machining tools. It employs computer-aided design (CAD) software to create a digital model of the desired part or component, which is then converted into machine-readable instructions.

How does CNC machining work?

CNC machining involves several steps, including computer programming, precise tool movements, and material removal. Here’s a general overview of the process:

1. Design: Create a digital model using CAD software.

2. Programming: Convert the design into machine-readable instructions.

3. Set-Up: Prepare the machine and tools for operation.

4. Execution: Carry out the machining process according to the program.

5. Monitoring and Adjustments: Oversee the process and make necessary adjustments.

6. Finishing and Quality Control: Complete the part and ensure it meets quality standards.

What are the benefits of CNC machining?

The subtractive process of CNC machining offers numerous advantages for both prototyping and production. Key benefits include precision and repeatability, tight tolerances, lower piece prices at higher quantities, and the ability to deliver quick-turn parts within one day.

What are your tolerances for machined parts?

We can achieve a machining tolerance of +/-0.0002 in (0.005 mm). We recommend that part features be thicker than 0.020 in (0.51 mm) in all areas, with a nominal part thickness above 0.040 in. Walls thinner than 0.020 in (0.5 mm) generally do not withstand the machining process.

Which industries use CNC machining?

CNC machining is extensively utilized across various industries. It’s prevalent in 3C electronics, aerospace, automotive, medical, robotics, agriculture and mechanical equipment that often incorporate metal parts. Additionally, it’s widely used in medical devices, household goods, energy, oil and gas, and other consumer applications. Overall, CNC machining is one of the most common manufacturing processes globally.

How do you ensure the quality of my parts?

–Once your order is confirmed, we conduct a comprehensive Design for Manufacturing (DFM) review to identify any potential issues that could impact quality.

–All incoming materials are inspected and verified using a range of testing equipment.

–Final inspection reports are provided before shipment.

–We can share inspection data with you in real-time, allowing us to collaboratively address any quality concerns during production.

How much does your CNC machining service cost?

The average cost for CNC machining on a 3-axis machine is approximately $40 per hour. Operator salaries for CNC milling machines typically range from $30 to $50 per hour. As a result, the total cost for CNC services in this scenario would be around $80 per hour. Keep in mind that higher quality and more advanced CNC machines may incur additional costs.

Can CNC machining be used for both prototyping and production?

Yes, CNC machining is suitable for both prototyping and production. It provides a cost-effective and efficient way to create prototypes of parts and components. Additionally, CNC machining is frequently employed for production runs. Once the design and prototype are finalized, CNC machines can be programmed to manufacture the required quantity of parts with consistent precision and quality.

How do you select a CNC machining manufacturer for my parts?

Choosing the right manufacturer for your parts requires careful consideration of several factors to ensure they meet your specific needs and deliver the desired quality. As a leading CNC machining manufacturer of high-precision parts, we adhere to the principles of precision manufacturing technology. We have evolved into a large-scale enterprise that offers a comprehensive range of services related to precision parts, spanning from production to sales.

What is the difference between 3-axis and 5-axis machining?

The main difference between 3-axis and 5-axis CNC machining lies in the movement and orientation of the cutting tool. A 3-axis CNC machine can move the cutting tool along the X, Y, and Z axes. In contrast, a 5-axis machine can move the cutting tool along the X, Y, Z, A, and B axes, allowing for more complex shapes and precision.

What are the applications of CNC machining?

CNC machining is utilized across various industries, including:

Automotive and Aerospace: It is used to produce precise engine components, structural parts, and other intricate elements.

Medical: The industry employs CNC for manufacturing devices, implants, and surgical instruments.

Electronics: CNC machining plays a crucial role in producing electronic housings, circuit boards, and connectors.

Machine Tool Manufacturing: It is essential for creating complex molds, dies, and machine components.

Custom Part Production: CNC is also valuable for prototyping, woodworking, and other applications, ensuring consistent quality and high precision.What are the advantages and disadvantages of CNC machining?

Advantages of CNC Machining

Precision and Repeatability: CNC machining delivers high precision and consistent replication of parts, which is essential for complex designs with tight tolerances.

Reduced human error: The automated nature of CNC machining minimizes human error and improves overall production quality.

Efficiency and speed: Automation can speed up production cycles, resulting in faster turnaround times compared to manual processes.

Material flexibility: CNC machines can use a wide range of materials, including metals, plastics, and composites, providing versatility for a variety of applications.

Software Integration: Advanced CNC software allows for quick design changes and updates, supporting rapid prototyping and easy customization.

Cost-effective for high-volume production: Although the initial setup costs may be higher, the unit cost decreases significantly as the production volume increases, making it economical for mass production.

Disadvantages of CNC Machining

High Initial Costs: CNC machinery and its maintenance require a large investments, resulting in high initial setup costs, particularly for small-scale operations.

Skill requirements: Highly skilled personnel are required to operate CNC machines, which increases training costs and limits accessibility.

Less Cost-Effective for Small Runs: CNC machining may not be economical for producing small quantities of parts due to the setup and programming time involved.

Material Waste: CNC machining typically involves subtractive processes, which result in more material waste compared to additive manufacturing methods.

Limited to Material Hardness: Extremely hard materials will cause rapid wear on CNC tools, potentially leading to increased operational costs and downtime.

What is the difference between 3D printing and CNC machining?

Manufacturing Process: 3D printing is an additive manufacturing process that constructs parts layer by layer using materials such as plastic or metal. In contrast, CNC machining is subtractive manufacturing, shaping the final product by cutting away material from a solid block.

Material Efficiency: 3D printing reduces waste by utilizing only the material necessary to create the part, while CNC machining tends to produce more waste due to its subtractive nature.

Speed and Cost: 3D printing is faster and less expensive for small batches and complex geometries. CNC machining is a better choice for high-volume production and materials that require high precision and strength.

Surface Finish and Tolerances: CNC machining generally provides superior surface finishes and tighter tolerances compared to 3D printing.

Who is the father of CNC machining?

John T. Parsons is often recognized as the father of CNC machining. In the late 1940s, he pioneered the first numerical control techniques and applied them to the production of helicopter rotor blades. Collaborating with engineer Frank L. Stulen, Parsons conceived a method of using punched tape to guide machine tools. This innovation laid the foundation for the development of CNC (Computer Numerical Control) technology. Their groundbreaking work ultimately led to the creation of the first CNC machines in the 1950s, transforming manufacturing by enhancing the precision, efficiency, and repeatability of machining processes.

What is the G and M code in CNC machines?

G and M codes are the programming languages used to control CNC machine tools. G-codes primarily dictate the machine’s movements, such as linear interpolation, circular motions, and other functions related to the tool’s path. In contrast, M-codes manage machine operations that aren’t directly linked to the tool’s movement, such as turning the machine on or off, starting or stopping the spindle, and regulating coolant. Together, G and M codes offer a complete set of instructions, enabling CNC machines to produce parts with precision and efficiency.

What tolerances can CNC machining achieve?

CNC machining is well-known for its ability to achieve high precision and tight tolerances, which are crucial for creating complex and detailed parts. Standard CNC machining typically maintains tolerances within ±0.01 inches (±0.127 mm), with our factory defaulting to these standardized tolerances unless otherwise specified. For even stricter requirements, advanced CNC machines can achieve tolerances as tight as ±0.0005 inches (±0.0127 mm) under optimal conditions. The achievable tolerance is influenced by various factors, including material, part geometry, size, and the specific type of CNC machine utilized. This capability makes CNC machining a preferred choice for industries demanding highly accurate components, such as aerospace, medical, and automotive sectors.

What is machining center and how does it work?

A machining center is a sophisticated CNC machine designed to perform various tasks, including milling, drilling, and tapping, all in a single setup. This integration improves efficiency and accuracy by minimizing the need to transfer parts between different machines. Machining centers feature a tool turret or magazine that accommodates multiple tools, allowing for automatic tool changes under CNC control. This functionality enables quick transitions between operations, optimizing production flow. Typically used for complex parts that require precision machining from multiple angles, machining centers are essential in modern manufacturing environments.

How much does your CNC machining service cost?

The cost of our CNC machining service varies based on the specific characteristics of your project, such as design and tolerance requirements. The machining time for the selected material is also a significant factor in determining the overall expense. For example, if the combined machining and material cost for a part is $2, along with a setup fee of $200, the total cost for a single part would be $202. However, if you order 200 identical parts, the cost per unit would drop to just $3!

Is there a minimum order quantity (MOQ) for CNC machining in your factory?

We recognize the varied needs of our customers, from single prototypes to large-scale production runs. As a result, we do not impose a strict minimum order quantity (MOQ). Whether you need just one machined part or thousands, we are prepared to deliver customized solutions that cater to your specific requirements. Our flexible approach guarantees that all clients, regardless of order size, receive the highest level of service and quality.

How long does it take to receive the part once an order is placed?

The lead time for receiving a CNC machined part from our factory can vary based on several factors, including the complexity of the design, the chosen material, and our current production schedule. CNC machining is renowned for its speed, especially for simpler parts, enabling quick turnaround times. In fact, parts can be delivered as soon as one day after the machining setup is complete! However, in order to get the most accurate time estimate tailored to your specific project, we recommend that you contact us directly for a detailed quote. This allows us to provide you with a precise timeframe based on your unique requirements.

How does CNC machining differ from traditional machining?

In traditional machining, a skilled machinist operates a machine to remove or shape metal based on specifications provided by designers and engineers, typically through engineering drawings or blueprints. They utilize turn wheels, dials, switches, chucks, vices, and a range of cutting tools made from hardened steel, carbide, and industrial diamond. Measurement instruments are then employed to ensure all dimensions are accurate.

CNC machining serves the same purposes as traditional machining—cutting, drilling, milling, boring, grinding, and other metal forming and removal processes—but utilizes computer numerical control instead of manual operation by a machinist. This automated process is driven by code created by programmers, ensuring consistent precision from the first cut to the 500th. Widely used in digital manufacturing and occasionally for low-volume production runs, CNC machining can be easily revised and adapted for modifications and different materials.

This method of machining is significantly more precise than traditional techniques and has largely replaced them in many manufacturing, fabrication, and industrial production settings, though not completely. It relies on mathematical coordinates and computer processing to achieve highly accurate results. In particular, computer numerical control (CNC) uses Cartesian coordinates—spatial references defined across multiple dimensions using coordinate axes. The automation of machine tools, such as cutters, drills, and borers, is managed through computer-directed numerical instructions that correspond to these coordinates. Engineers initially define these coordinates in the product’s digital design and drawings, enabling the computer to guide the machines with exceptional precision.

CNC Machining Resources

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Newsletter

Suspendisse a neque diam. Donec lacinia quam vitae tristique scelerisque. Nullam at tincidunt felis.

你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 |

|---|---|---|

你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 |

你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 |

你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 | 你的文字在这里...选择文本的任何部分来访问格式工具栏。 |